01

Injection Mold Design DFM Services (Design For Manufacturability)

Injection Mold Design Services

Project Analysis: Understanding Your Requirements

Every journey begins with understanding. Our process starts with a thorough analysis of your project requirements, ensuring a clear roadmap for mold design success.

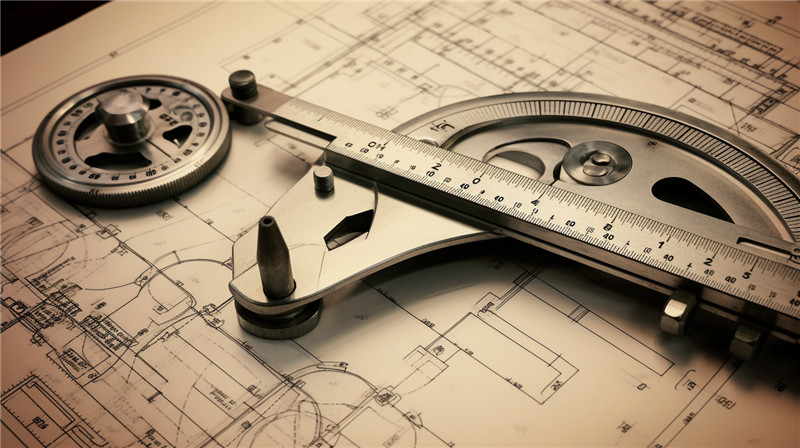

Concept Ideation: Crafting the Blueprint of Innovation

Ideas take shape in this phase as our expert designers ideate and conceptualize the initial blueprints, considering factors like design complexity and material requirements.

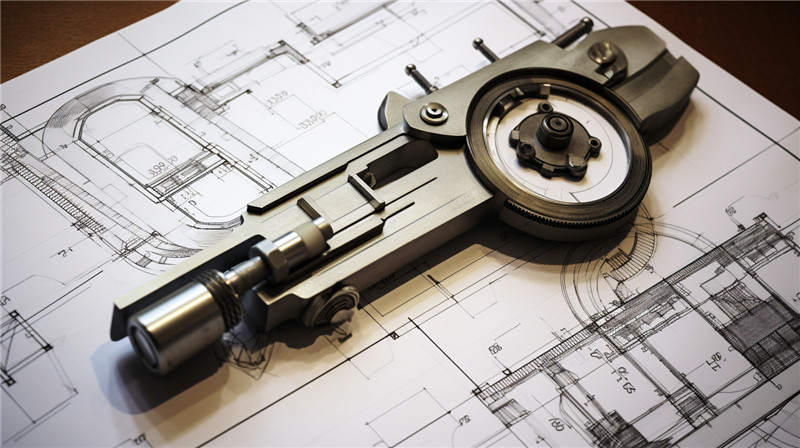

Detailed Design: Precision in Every Detail

Precision is non-negotiable. Dive into the meticulous detailing of the design, where every curve and contour is defined with utmost accuracy.

Step-by-Step Mold Design: From Concept to Blueprint

Witness the meticulous journey from concept to blueprint as we guide you through our step-by-step injection mold design process. Each phase is a testament to our commitment to perfection.

Quality Assurance in Mold Design: Ensuring Flawless Execution

Quality is non-negotiable. Explore the stringent quality assurance measures embedded in our mold design process, guaranteeing flawless execution in every detail.

Optimizing for Efficiency: Streamlining the Production Process

Efficiency is at the core of our design philosophy. Learn how we optimize mold designs for efficiency, ensuring a streamlined production process and faster time to market.

Precision in Production: Our Injection Molding Solutions

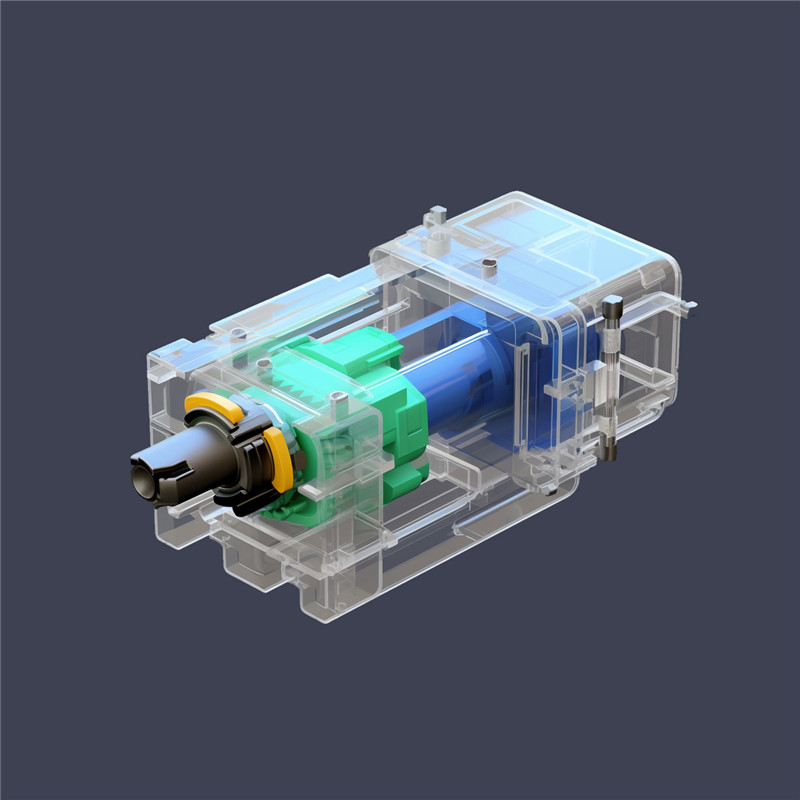

State-of-the-Art Injection Molding Machines: Engineering Excellence

The heart of precision lies in our molding machines. Explore the engineering excellence behind our state-of-the-art injection molding machines, designed to meet the highest standards.

Materials Mastery in Injection Molding: Choosing the Perfect Resin

Material selection is pivotal. Gain insights into our expertise in choosing the perfect resin for injection molding, balancing factors like strength, durability, and cost-effectiveness.

Rapid Prototyping through Injection Molding: Accelerating Product Development

Experience the speed of innovation with our rapid prototyping solutions. Learn how injection molding accelerates product development, allowing for quick iterations and efficient testing.

Injection Mold Design Services

FAQs:

How Can Design and Engineering Tool Building Benefit My Project?

+

Our experts tailor tools to your project's unique needs, ensuring efficiency and innovation from the start.

Is Fast Prototyping Suitable for Large-Scale Production?

+

Absolutely! Fast prototyping is versatile, catering to both small-scale projects and large-scale production runs.

What Materials Are Ideal for Precision Molding?

+

Materials like thermoplastics and elastomers are commonly used for precision molding due to their versatility and durability.

How Long Does It Take to Transition from Prototyping to Full-Scale Manufacturing?

+

The timeline varies but our streamlined processes ensure a swift transition, minimizing time to market.

Can Sustainable Manufacturing Practices Impact Cost?

+

Contrary to common belief, sustainable practices can lead to long-term cost savings through efficiency improvements and waste reduction.

Is Industry 4.0 Accessible for Small Businesses?

+

Yes, Industry 4.0 technologies are scalable, allowing even small businesses to benefit from automation and smart manufacturing solutions.