01

Professional High Precision Yas Txhaj Moulding Yas Prototyping nrog 3D Drawings

Peb Cov Khoom Siv Yas Txhaj Moding Servers

Kev txiav txim siab rau Prototype:

Tom qab meticulously illustrating ib tug kev cai yas ib feem thiab seemingly ncav cuag lub brink ntawm kev npaj ntau lawm, opting rau prototype txhaj molding ua ib tug tswv yim xav txog. Cov kauj ruam preemptive no muab ib txoj hauv kev zoo rau:

Kev txheeb xyuas cov kev kho kom zoo: Tshawb nrhiav qhov tsim nuances thiab kev txhim kho uas tej zaum yuav tsis pom tseeb ntawm daim ntawv.

Mitigating Risks: Proactively daws cov teeb meem thiab tsis paub tseeb ua ntej cog lus rau kev tsim khoom loj.

Xyuas kom meej Precision: Fine-tune cov txheej txheem ntau lawm kom pom precision thiab efficiency.

Hauv kev xaus, kev txhaj tshuaj molding prototyping tshuab tsis yog ib kauj ruam hauv kev tsim khoom; nws yog ib qho tseem ceeb tshaj plaws. Nws txhawb cov neeg tsim qauv thiab cov chaw tsim khoom lag luam txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhim kho cov khoom lag luam nrog kev nrawm, kev pom, thiab tus nqi-zoo, tso lub hauv paus rau kev ua tiav thiab kev tsim khoom loj.

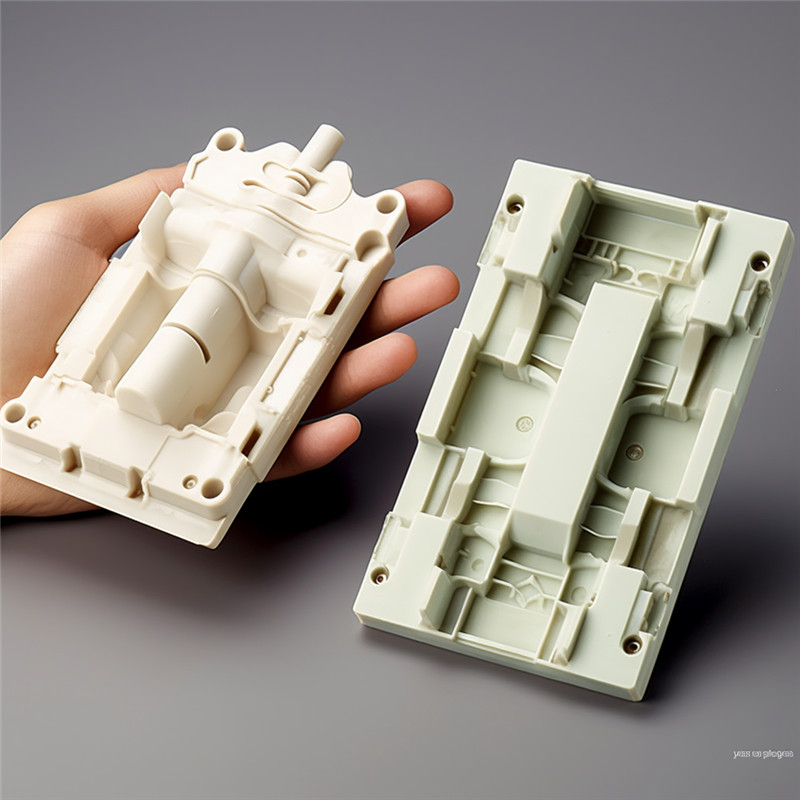

Gallery ntawm Txhaj Molding Prototyping

CNC Machining cov ntaub ntawv

Txhaj Molding Prototyping Khoom

Xaiv cov ntaub ntawv zoo rau txhaj Moulding Prototyping

Xaiv cov khoom tsim nyog rau kev txhaj tshuaj molding prototyping yog qhov kev txiav txim siab tseem ceeb hauv cov txheej txheem tsim khoom. Kev xaiv hinges rau yam xws li qhov yuav tsum tau ua, kev txwv nyiaj txiag, thiab cov yam ntxwv tshwj xeeb tseem ceeb rau tus qauv. Alignment nrog lub hom phiaj kev ua haujlwm, kev xav tau ntawm kev ua haujlwm, thiab cov kev cia siab uas tus qauv yuav ntsib yog qhov tseem ceeb. Txhaj tshuaj molding prototyping muaj ntau yam khoom siv, txhawb cov neeg tsim qauv thiab cov kws tsim qauv los tsim cov qauv qauv uas ncaj ncees ua raws li cov khoom ntawm cov khoom tsim kawg. Tsis tas li ntawd, kev txiav txim siab xws li tus nqi, lub sijhawm ua haujlwm, thiab kev yooj yim ntawm machining lossis tiav ua lub luag haujlwm tseem ceeb hauv kev xaiv cov khoom.

Thermoplastics:

ABS (Acrylonitrile Butadiene Styrene):

Khoom: Paub txog lub zog thiab cuam tshuam tsis kam.

Daim Ntawv Thov: Feem ntau siv rau kev tsim cov khoom siv thiab cov khoom siv tsheb.

Polypropylene:

Khoom: Lub teeb yuag, tshuaj-resistant.

Daim ntaub ntawv: Haum rau kev ntim khoom, ntim khoom, thiab cov khoom siv tsheb.

Polyethylene:

Cov ntaub ntawv: HDPE (High-Density Polyethylene), LDPE (Low-Density Polyethylene).

Daim ntaub ntawv: Siv rau cov khoom xws li lub raj mis mus rau cov khoom ua si.

Polycarbonate:

Properties: High impact resistance, optical clarity.

Daim ntawv thov: Zoo tagnrho rau cov qauv ntawm cov khoom siv kho qhov muag, cov khoom siv hluav taws xob, thiab cov iav kev nyab xeeb.

Engineering Plastics:

Nylon (Polyamide):

Khoom: Muaj zog, ruaj, zoo hnav tsis kam.

Daim ntaub ntawv: Siv rau cov qauv ntawm cov iav, bearings, thiab cov khoom siv.

Polyoxymethylene (POM):

Kuj Paub Raws li: Acetal.

Khoom: tawv thiab nruj.

Daim Ntawv Thov: Siv rau cov qauv ntawm cov khoom siv kho tshuab xws li cov iav thiab cov bushings.

PEEK (Polyether Ether Ketone):

Khoom: High-kev ua tau zoo, zoo heev tshuaj tiv thaiv.

Daim ntaub ntawv: Haum rau cov qauv hauv kev xav tau ib puag ncig, xws li aerospace thiab kev kho mob.

Elastomers:

Silicone Roj Hmab:

Properties: Saj zawg zog, resistant rau huab cua kub.

Daim ntaub ntawv: Siv rau cov qauv ntawm cov khoom siv kho mob, cov ntsaws ruaj ruaj, thiab cov khoom siv.

Bioplastics:

PLA (Polylactic Acid):

Khoom: Biodegradable.

Daim ntaub ntawv: Siv nyob rau hauv ib puag ncig tus phooj ywg prototypes, feem ntau xaiv rau ntim thiab cov khoom siv.

Nyob rau hauv lub cheeb tsam ntawm kev txhaj tshuaj molding prototyping, kev xaiv ntawm cov ntaub ntawv yog ib tug nuanced kev txiav txim siab uas yuav tsum tau ceev faj saib xyuas ntawm ob qho tib si technical thiab cov tswv yim. Txhua yam khoom coj nws cov khoom tshwj xeeb, ua rau muaj qhov tseeb thiab kev ua haujlwm ntawm tus qauv.

Gallery ntawm Txhaj Molding Prototyping