01

Isevisi Yokubumba Umjovo Wensimbi Ngokwezifiso Isevisi Yokubumba Umjovo

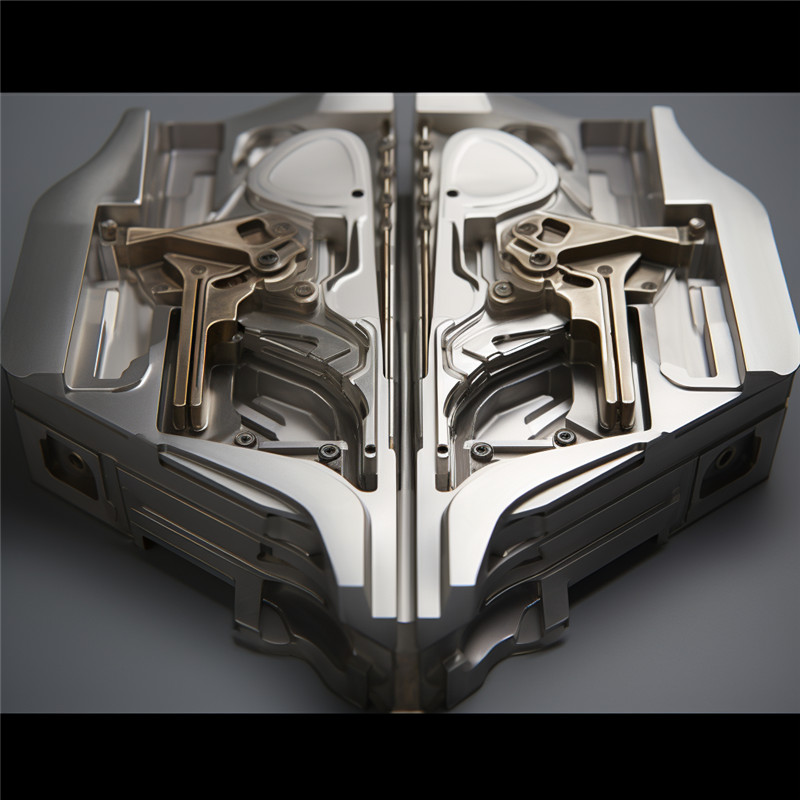

Isevisi Yethu Yokubumba Umjovo Wensimbi

Ngokusebenzisa izixazululo ze-Bushang's Metal Injection Molding (MIM) e-China, sinekhono lokubumba izingxenye zensimbi ngokusekelwe kusayizi wazo, ukuyinkimbinkimbi, kanye nezidingo zevolumu. Inqubo yethu ye-MIM isivumela ukuthi sikhiqize izingxenye zensimbi zekhwalithi ephezulu ezinamajiyometri ayinkimbinkimbi kanye nokubekezelelana okuqinile. Kungakhathaliseki ukuthi udinga izingxenye ezincane, eziyinkimbinkimbi noma izingxenye ezinkulu, izixazululo zethu ze-MIM zingabhekana nezidingo zakho ezithile. Ngobuchwepheshe bethu kubuchwepheshe be-MIM, singakunikeza izixazululo eziphumelelayo nezingabizi zokukhiqiza ingxenye yakho yensimbi.

Izixazululo Zokubumba Zokubumba Zensimbi Engokwezifiso

1, I-Prototyping esheshayo

Thatha ithuba lezinsizakalo zethu zokubumba umjovo osheshayo, ezikuvumela ukuthi uthole ngokushesha amayunithi we-1K-100K ngezindleko eziphansi. Ngokusebenzisa isikhunta se-aluminium noma sensimbi, siqinisekisa izikhathi zokushintsha ngokushesha, sibhekana ngqo nezinselelo zakho zokukhiqiza kanye nokunciphisa isikhathi sokuya emakethe. Inqubo yethu yokubumba yomjovo ephumelelayo iqinisekisa imiphumela yekhwalithi ephezulu kuyilapho igcina ukusebenza kahle kwezindleko. Sithembe ukuthi sizokulethela amanani owadingayo, ngokushesha nangokuthengekayo, sikusize uhlangabezane nezinhloso zakho zokukhiqiza ngempumelelo.

2, Ukukhiqizwa Kwevolumu Ephansi

Izinsizakalo zethu zokubumba umjovo wevolumu ephansi zihloselwe ukukhulisa umkhiqizo wakho wokukhiqiza ngokukuvumela ukuthi usebenzise isikhunta sensimbi esiqinile ukuze ukhiqize amayunithi angu-100K–1M. Le ndlela yokwenza iqinisekisa ikhwalithi ephezulu nokufana phakathi nayo yonke inqubo yokukhiqiza, ihlangabezana ngokuphumelelayo nemfuneko yakho yokukhiqiza ngezinga elikhulu, ezinembile. Ngolwazi lwethu namathuluzi aphambili, singakwazi ukufeza izidingo zakho kuyilapho siphakamisa izindinganiso eziphakeme kakhulu. Ungathembela kithi ukuthi sikunikeze izixazululo zokubumba umjovo wevolumu ephansi ezinokwethenjelwa nezisebenzayo ezikusiza ukufeza izinjongo zakho zokukhiqiza.

Metal Umjovo Molding Isicelo

I-Metal injection molding (MIM) iyinqubo yokukhiqiza eguquguqukayo ethola izinhlelo zokusebenza kuzo zonke izimboni ezihlukahlukene. Nazi izibonelo ezivamile:

Amadivayisi Ezokwelapha Namazinyo:

1.Izinsimbi zokuhlinza

2.Obakaki be-Orthodontic

3.Ukufakwa kwamazinyo

I-Aerospace nokuvikela:

1.1Izingxenye ze-aerospace eziyinkimbinkimbi

2.Izingxenye zezikhali ezicitshwayo kanye nezikhali

3.Izingxenye zesibhamu

Ezezimoto:

1.Injini kanye nezingxenye zokudlulisela

Izingxenye zesistimu ye-2.Fuel

3.Izinzwa nama-actuator

Ezogesi:

1.Izixhumi namatheminali

2.EMI izingxenye zokuvikela

3.Amaswishi amancane

Izimpahla zabathengi:

1.Bukela izingxenye

2.Ilokhi kanye nezingxenye ezibalulekile

3.Amahinge aqondile nama-clasp

Izisetshenziswa zezimboni:

1.Ama-valve nezinsimbi

Izingxenye ze-2.Pump

3.Amagiya nama-gearbox

Imishini Yendwangu:

1.Izimbobo nezikhonkwane zomhlahlandlela

2.Izimbambo yenaliti

I-3.Spinnerets yokukhiqiza i-fiber

Amandla Nokukhiqiza Amandla:

1.Ama-turbine blades nama-nozzles

2.Izingxenye zokushintsha ukushisa

3.Izixhumi zikagesi noxhumana nabo

Ezokuxhumana:

1.Izingxenye ze-antenna

2.Izindlu zokuxhuma

3.Izingxenye ze-Waveguide

Amasistimu okushisa umlilo:

1.Amakhanda okufafaza

Izingxenye ze-2.Valve

Lezi zibonelo zimele ingxenye encane yezicelo ezingase zibe khona zokubumba umjovo wensimbi. Njengoba ubuchwepheshe buthuthuka kanye nesidingo sokunemba okuphezulu, izingxenye zensimbi eziyinkimbinkimbi zikhula, i-MIM iyaqhubeka nokukhula ibe izimboni ezintsha. Ikhono layo lokukhiqiza amajiyometri ayinkimbinkimbi kanye nokubekezelela okuqinile kuyilapho kunciphisa udoti wezinto ezibonakalayo kukwenza kube ukukhetha okukhangayo ezimbonini lapho izindlela zokukhiqiza zendabuko zingase zingabizi kakhulu noma zisebenziseke.

Izinto Zokusebenza Zokubumba Umjovo Wensimbi

I-Metal Injection Molding (MIM) inikeza izinhlobonhlobo zezinto zensimbi nama-alloys ukuze zisetshenziswe enqubweni yokukhiqiza. Ezinye izinto ezijwayelekile ezisetshenziswa ku-MIM zifaka:

Ama-Aluminium Alloys: I-Aluminium 6061, i-Aluminium 7075

Ama-alloys Ensimbi: 316L Insimbi Engagqwali, 17-4 PH Insimbi Engenasici, 440C Insimbi Engagqwali, 304 Insimbi Engagqwali

Insimbi Yamathuluzi: Insimbi Yethuluzi le-M2, Insimbi Yethuluzi le-D2, Insimbi Yethuluzi le-A2

I-Carbon Steel Alloys: 1018 Carbon Steel, 1045 Carbon Steel, 1095 Carbon Steel

Izinsimbi ze-Low Alloy: 4140 Insimbi Ephansi Yengxubevange, 8620 Insimbi Ephansi Yengxubevange

Izinsimbi ezinesivinini esikhulu: i-M42 High-Speed Steel, i-M4 High-Speed Steel

Ama-alloys e-Copper: Ama-alloys e-Copper-Tin, Ama-alloys e-Copper-Nickel

Ama-Titanium Alloys: Ti-6Al-4V (Grade 5), Ti-6Al-7Nb

Ama-Tungsten Alloys: Ama-Tungsten-Nickel-Copper Alloys

I-Precious Metal Alloys: Ama-alloys egolide, ama-Silver Alloys

Ama-Magnetic Alloys: Ama-Soft Magnetic Alloys (isb, 49%Ni-Fe)

Ama-Cobalt Alloys: I-Cobalt-Chromium Alloys (isb, i-CoCrMo)

Ama-Iron Alloys: I-Sintered Iron, I-Soft Magnetic Iron, I-Ductile Iron

I-Carbide Materials: I-Tungsten Carbide (WC), i-Cemented Carbide

I-Cermet Materials: I-Titanium Carbide (TiC) Cermet, i-Chromium Carbide (Cr3C2) Cermet

Lezi zinto zinikeza izinhlobonhlobo zezakhiwo nezici, okuvumela ukukhiqizwa kwezingxenye zensimbi ezihlukahlukene nezisezingeni eliphezulu ngenqubo ye-MIM.