01

Inkonzo yokuBumba iSitofu sesinyithi Inkonzo yokuBumba isitofu ngokweSiko

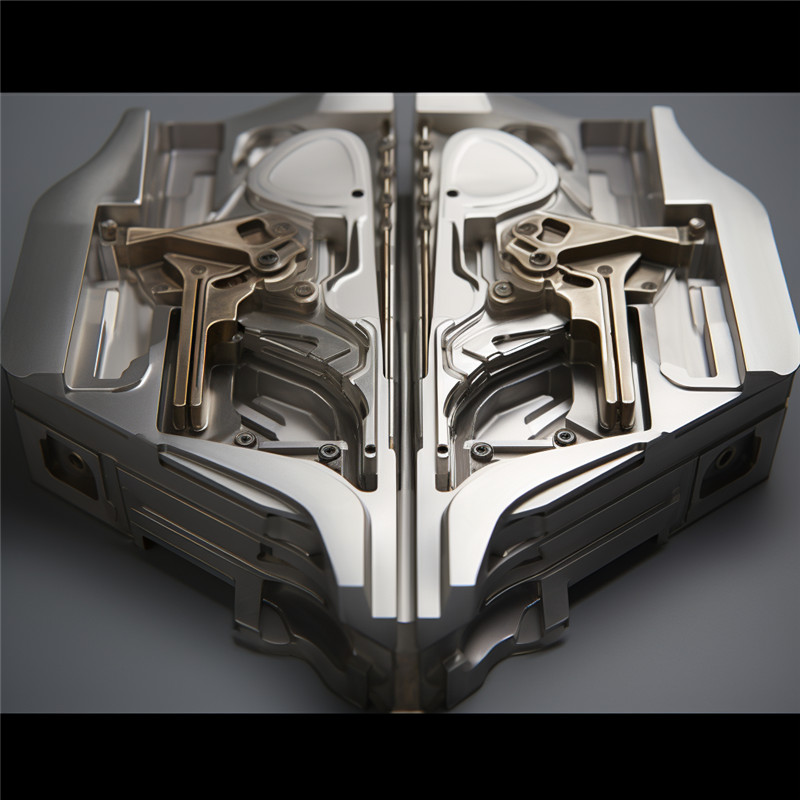

Inkonzo yethu yokuBumba isitofu sesinyithi

Ngokusebenzisa izisombululo zeBushang zeMetal Injection Molding (MIM) eTshayina, sinakho ukubumba iinxalenye zentsimbi ngokusekelwe kubukhulu bazo, ukuntsonkotha, kunye neemfuno zevolumu. Inkqubo yethu ye-MIM isenza sikwazi ukuvelisa iinxalenye zentsimbi ezikumgangatho ophezulu ezinejometri ezintsonkothileyo kunye nokunyamezelana okuqinileyo. Nokuba ufuna izinto ezincinci, ezintsonkothileyo okanye iinxalenye ezinkulu, izisombululo zethu zeMIM zinokuhlangabezana neemfuno zakho ezithile. Ngobuchule bethu kwitekhnoloji ye-MIM, sinokubonelela ngezisombululo ezisebenzayo nezingabizi kakhulu kwimveliso yakho yentsimbi.

Isitofu Metal Isitofu Molding Solutions

1, iPrototyping eKhawulezayo

Thatha ithuba leenkonzo zethu zokubumba iinaliti ezikhawulezayo, ezikuvumela ukuba ufumane ngokukhawuleza iiyunithi ze-1K-100K ngexabiso eliphantsi. Ngokusebenzisa i-aluminium okanye i-molds yensimbi, siqinisekisa amaxesha okutshintsha ngokukhawuleza, ukujongana ngqo nemingeni yakho yokuvelisa kunye nokunciphisa ixesha lokuya kwintengiso. Inkqubo yethu esebenzayo yokubumba isitofu iqinisekisa iziphumo ezikumgangatho ophezulu ngelixa igcina ixabiso elifanelekileyo. Sithembe ukuba siza kuzisa izixa ozifunayo, ngokukhawuleza nangeendleko ezifikelelekayo, sikuncede ufezekise iinjongo zakho zemveliso ngokufanelekileyo.

2, uMveliso woMqulu ophantsi

Iinkonzo zethu zokubumba iinaliti ezinomthamo ophantsi zenzelwe ukunyusa imveliso yakho ngokukuvumela ukuba usebenzise iimolds zentsimbi ezomeleleyo ukuvelisa iiyunithi eziyi-100K-1M. Le ndlela yokusebenza iqinisekisa umgangatho ophezulu kunye nokufana ngexesha lonke lenkqubo yemveliso, ihlangabezana ngokufanelekileyo nemfuno yakho yemveliso emikhulu, echanekileyo. Ngolwazi lwethu kunye nezixhobo zokusika, sinokuzalisekisa iimfuno zakho ngelixa siphakamisa imigangatho ephezulu. Ungathembela kuthi ukuba sikubonelele ngezisombululo zokubumba iinaliti ezinomthamo ophantsi othembekileyo nezisebenzayo ezinokukunceda ufezekise iinjongo zakho zemveliso.

Metal Isitofu Molding Isicelo

I-Metal injection molding (MIM) yinkqubo yokwenza izinto ezininzi ezifumana izicelo kuwo wonke amashishini ahlukeneyo. Nantsi imizekelo eqhelekileyo:

Izixhobo zonyango nezamazinyo:

1.Izixhobo zotyando

2.Izibiyeli zeOrthodontic

3.Ukufakelwa kwamazinyo

I-Aerospace kunye noKhuseleko:

1.1Amalungu amancinane antsonkothileyo asemkhathini

2.Izixhobo zeMissile kunye nezixhobo

3.Amalungu ompu

Iimoto:

1.Iinjini kunye neenxalenye zokuhambisa

Amacandelo enkqubo ye-Fuel

3.Izinzwa kunye nee-actuators

I-Electronics:

1.Iziqhagamshelo kunye neetheminali

I-2.EMI yokukhusela amacandelo

3.Ukutshintsha okuncinci

Impahla zomthengi:

1.Bukela amacandelo

2.Tshixa kunye namacandelo aphambili

3.Iihenjisi ezichanekileyo kunye neeclasps

Izixhobo zoShishino:

1.Iivalvu kunye nezifakelo

2.Iinxalenye zempompo

3.Iigiya kunye neebhokisi zegiya

oomatshini beMilaphu:

1.Imilomo kunye nezikhonkwane zesikhokelo

2.Izibambi yenaliti

I-3.Spinnerets yokuvelisa ifayibha

Amandla kunye nokuVeliswa koMbane:

1.Iintsimbi zeTurbine kunye nemilomo

2.Amacandelo okutshintsha ubushushu

3.Iziqhagamshelo zombane kunye nabafowunelwa

Unxibelelwano:

1.Amacandelo e-antenna

2.Izindlu zokuxhuma

3.Amacandelo e-Waveguide

Iinkqubo zokutshiza umlilo:

1.Iintloko zokutshiza

Amacandelo 2.Valve

Le mizekelo imele iqhezu nje lezicelo ezinokubakho zokubumba inaliti yesinyithi. Njengoko itekhnoloji ihambela phambili kunye nemfuno yokuchaneka okuphezulu, iinxalenye zetsimbi ezintsonkothileyo zanda, iMIM iyaqhubeka nokukhula ibe ngamashishini amatsha. Ukukwazi kwayo ukuvelisa iijiyometri ezintsonkothileyo kunye nokunyamezelana okuqinileyo ngelixa kuncitshiswa inkunkuma yezinto kuyenza ibe lukhetho olunomtsalane kumashishini apho iindlela zokwenziwa kwemveli zinokuthi zingabizi kakhulu okanye zisebenziseke.

Izixhobo zeNkonzo yokuBumba iSitofu sesinyithi

I-Metal Injection Molding (MIM) inikeza uluhlu olubanzi lwezinto zetsimbi kunye ne-alloys zokusetyenziswa kwinkqubo yokuvelisa. Ezinye izinto eziqhelekileyo ezisetyenziswa kwiMIM ziquka:

Iingxube zeAluminiyam: I-Aluminiyam 6061, i-Aluminiyam 7075

I-Stainless Steel Alloys: 316L iStainless Steel, 17-4 PH iStainless Steel, 440C iStainless Steel, 304 iStainless Steel

Iintsimbi zesixhobo: Isixhobo sentsimbi yeM2, isixhobo seNsimbi seD2, isixhobo sentsimbi yeA2

Iintsimbi zeCarbon Steel: 1018 Carbon Steel, 1045 Carbon Steel, 1095 Carbon Steel

Iintsimbi ze-alloy eziphantsi: i-4140 i-Low Alloy Steel, i-8620 i-Low Alloy Steel

Iintsimbi ezinesantya esiphezulu: iM42 iSpeed-Speed Steel, iM4 yeSpeed-Speed Steel

Iialloyi zeCopper: I-Copper-Tin Alloys, i-Copper-Nickel Alloys

I-Titanium Alloys: Ti-6Al-4V (iBanga lesi-5), i-Ti-6Al-7Nb

Iialloyi zeTungsten: I-Tungsten-Nickel-Copper Alloys

Iingxube zeMetal ezixabisekileyo: ii-alloys zegolide, ii-alloys zesilivere

I-Magnetic Alloys: Soft Magnetic Alloys (umzekelo, 49%Ni-Fe)

I-Cobalt Alloys: Iingxube zeCobalt-Chromium (umzekelo, iCoCrMo)

I-Iron Alloys: I-Sintered iron, i-Soft Magnetic iron, i-Ductile iron

Izixhobo zeCarbide: iTungsten Carbide (WC), iCarbide eneCemented

Izinto zeCermet: iTitanium Carbide (TiC) Cermet, Chromium Carbide (Cr3C2) Cermet

Ezi zixhobo zinika uluhlu olubanzi lweepropati kunye neempawu, ezivumela ukuveliswa kweendawo ezahlukeneyo zetsimbi kunye neziphezulu ngenkqubo yeMIM.