01

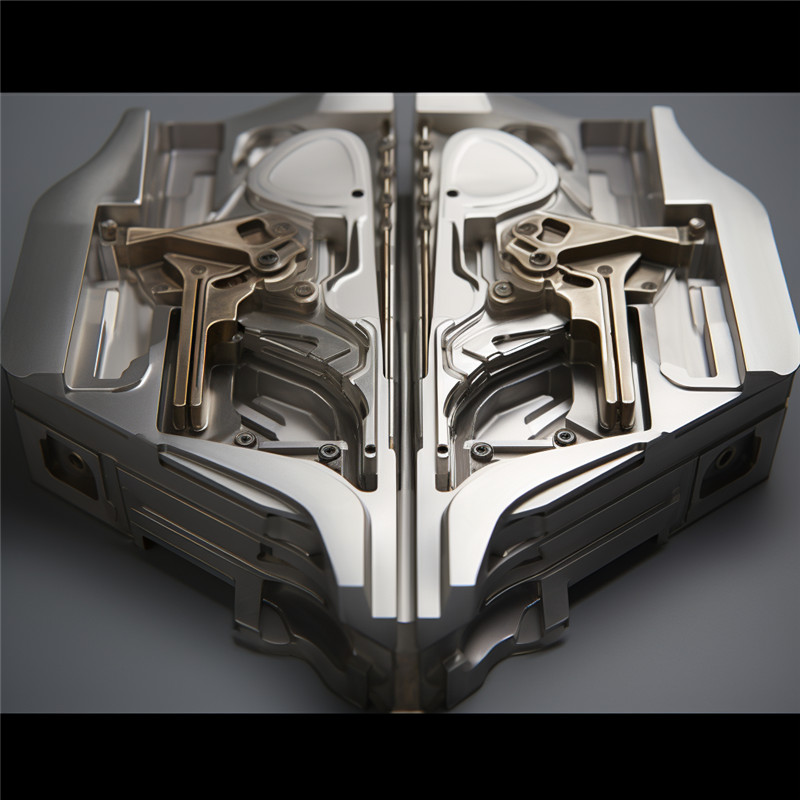

Metal Ente Molding Service Custom Injection Molding Service

Tšebeletso ea Rona ea Metal Ente ea ho Bopa

Ka ho sebelisa litharollo tsa Busang's Metal Injection Molding (MIM) naheng ea China, re na le bokhoni ba ho bopa likarolo tsa tšepe ho latela boholo ba tsona, ho rarahana le litlhoko tsa bophahamo ba tsona. Ts'ebetso ea rona ea MIM e re lumella ho hlahisa likarolo tsa tšepe tsa boleng bo holimo tse nang le lijeometri tse rarahaneng le mamello e thata. Hore na o hloka likaroloana tse nyane, tse rarahaneng kapa likarolo tse kholoanyane, litharollo tsa rona tsa MIM li ka khotsofatsa litlhoko tsa hau tse ikhethileng. Ka tsebo ea rona ea theknoloji ea MIM, re ka fana ka tharollo e sebetsang le e theko e tlaase bakeng sa tlhahiso ea karolo ea hau ea tšepe.

Custom Metal Ente Molding Solutions

1, Potlako ea Prototyping

Nka monyetla oa lits'ebeletso tsa rona tsa ho etsa ente ka potlako, tse u lumellang ho fumana likarolo tsa 1K-100K kapele ka theko e tlase. Ka tšebeliso ea liforomo tsa aluminium kapa tšepe, re netefatsa nako ea phetoho e potlakileng, re sebetsana ka ho toba le liphephetso tsa tlhahiso ea hau le ho fokotsa nako ea ho ea 'marakeng. Mokhoa oa rona oa ho bopa ente o sebetsang hantle o netefatsa liphetho tsa boleng bo holimo ha o ntse o boloka litšenyehelo. Re tšepe hore re tla fana ka bongata boo u bo hlokang, hang-hang le ka theko e tlaase, ho u thusa ho fihlela lipheo tsa hau tsa tlhahiso ka katleho.

2, Tlhahiso e Tlase ea Molumo

Litšebeletso tsa rona tsa ho bopa ente ea molumo o tlase li reretsoe ho eketsa tlhahiso ea hau ea tlhahiso ka ho u thusa ho sebelisa liforomo tsa tšepe tse tšoarellang ho hlahisa likarolo tsa 100K-1M. Mokhoa ona o tiisa boleng bo holimo le ho ts'oana nakong eohle ea ts'ebetso ea tlhahiso, ho fihlela litlhoko tsa hau tsa tlhahiso e kholo, e nepahetseng. Ka tsebo ea rona le lisebelisoa tsa morao-rao, re ka phethahatsa litlhoko tsa hau ha re ntse re boloka litekanyetso tse phahameng ka ho fetisisa. U ka itšetleha ka rona ho u fa litharollo tse ka tšeptjoang le tse sebetsang tsa ente ea molumo o tlase tse u thusang ho fihlela sepheo sa hau sa tlhahiso.

Metal Ente Molding Kopo

Metal injection molding (MIM) ke ts'ebetso ea ho etsa lintho tse ngata e fumanehang ka har'a liindasteri tse fapaneng. Mehlala e meng e tloaelehileng ke ena:

Lisebelisoa tsa Bongaka le Meno:

1.Lisebelisoa tsa ho buoa

2.Masakaneng a Orthodontic

3.Ho kenngoa ha meno

Sepakapaka le Tšireletso:

1.1Likaroloana tse nyane tse rarahaneng tsa sepakapaka

2.Likarolo tsa metsu le libetsa

3.Likarolo tsa sethunya

Likoloi:

1.Engine le likarolo tsa phetiso

Likarolo tsa tsamaiso ea 2.Fuel

3. Li-sensor le li-actuator

Tsa elektroniki:

1.Lihokelo le li-terminals

2.EMI likarolo tse sireletsang

3.Li-switch tse nyane

Thepa ea bareki:

1.Sheba likarolo

2.Lock le likarolo tsa bohlokoa

3.Precision hinges le clasps

Lisebelisoa tsa Indasteri:

1. Li-valve le lisebelisoa

2.Likarolo tsa pompo

3.Gears le li-gearbox

Mechini ea masela:

1.Nozzles le lithakhisa tsa tataiso

2.Lits'oants'o tsa nale

3.Spinnerets bakeng sa tlhahiso ea fiber

Matla le Pheliso ea Matla:

1. Li-blades tsa turbine le li-nozzles

2.Likarolo tsa mocheso oa mocheso

3.Lihokelo tsa motlakase le mabitso

Mehala ea puisano:

Likarolo tsa 1.Antenna

2.Lihaho tsa Connector

3.Waveguide likarolo

Sistimi ea ho fafatsa mollo:

1.Lihlooho tsa ho fafatsa

Likarolo tsa 2.Valve

Mehlala ena e emela karoloana feela ea lits'ebetso tse ka bang teng bakeng sa ho bopa ente ea tšepe. Ha thekenoloji e ntse e tsoela pele le tlhokahalo ea ho nepahala ho phahameng, likarolo tsa tšepe tse rarahaneng li ntse li eketseha, MIM e ntse e tsoela pele ho hola ho ba liindasteri tse ncha. Bokhoni ba eona ba ho hlahisa li-geometri tse rarahaneng le mamello e thata ha e ntse e fokotsa litšila tsa thepa e etsa hore e be khetho e khahlehang liindastering moo mekhoa ea khale ea tlhahiso e ka bang le litšenyehelo tse tlase kapa e sebetsang.

Metal Ente Molding Lisebelisoa tsa Tšebeletso

Metal Injection Molding (MIM) e fana ka mefuta e mengata ea lisebelisoa tsa tšepe le li-alloys bakeng sa ho sebelisoa ha ho etsoa tlhahiso. Lisebelisoa tse ling tse tloaelehileng tse sebelisoang ho MIM li kenyelletsa:

Lisebelisoa tsa Aluminium: Aluminium 6061, Aluminium 7075

Lisebelisoa tsa tšepe: 316L Stainless Steel, 17-4 PH Stainless Steel, 440C Stainless Steel, 304 Stainless Steel

Lisebelisoa tsa lisebelisoa: M2 Tool Steel, D2 Tool Steel, A2 Tool Steel

Lisebelisoa tsa Carbon Steel: 1018 Carbon Steel, 1045 Carbon Steel, 1095 Carbon Steel

Litšepe tse Tlase tsa Alloy: 4140 Low Alloy Steel, 8620 Low Alloy Steel

Litšepe tse Phahameng ka ho Fetisisa: Tšepe ea M42 ea lebelo le phahameng, tšepe ea M4 ea lebelo le phahameng

Lisebelisoa tsa Koporo: Lisebelisoa tsa Koporo-Tin, Lisebelisoa tsa Koporo-Nickel

Lisebelisoa tsa Titanium: Ti-6Al-4V (Kereiti ea 5), Ti-6Al-7Nb

Lisebelisoa tsa Tungsten: Lisebelisoa tsa Tungsten-Nickel-Copper

Lisebelisoa tsa Metal tsa Bohlokoa: Lisebelisoa tsa Khauta, Lisebelisoa tsa Silver

Lisebelisoa tsa Magnetic: Soft Magnetic Alloys (mohlala, 49%Ni-Fe)

Lisebelisoa tsa Cobalt: Cobalt-Chromium Alloys (mohlala, CoCrMo)

Lisebelisoa tsa tšepe: Tšepe e Sintered, Tšepe e Bonolo ea Magnetic, Tšepe ea Ductile

Lisebelisoa tsa Carbide: Tungsten Carbide (WC), Carbide e entsoeng ka Cemented

Lisebelisoa tsa Cermet: Titanium Carbide (TiC) Cermet, Chromium Carbide (Cr3C2) Cermet

Lisebelisoa tsena li fana ka mefuta e mengata ea thepa le litšoaneleho, tse lumellang ho hlahisa likarolo tse sa tšoaneng tsa tšepe le tsa boleng bo phahameng ka mokhoa oa MIM.