01

Metal Injection Molding Service Tsika jekiseni Kuumba Sevhisi

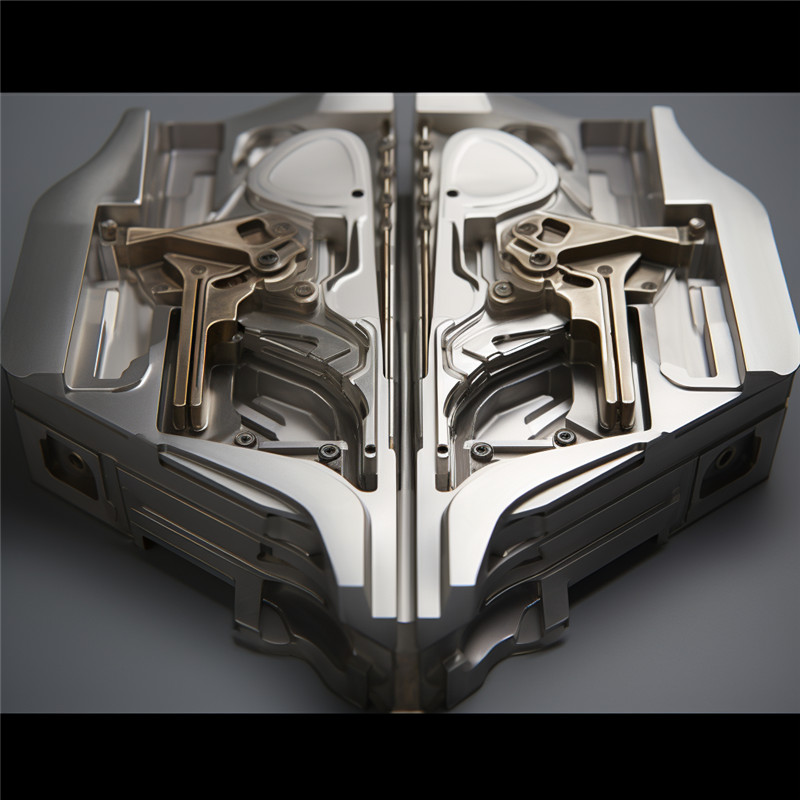

Yedu Metal Injection Molding Service

Nekushandisa Busang's Metal Injection Molding (MIM) mhinduro kuChina, tine kugona kuumba zvidimbu zvesimbi zvichienderana nehukuru hwazvo, kuoma, uye vhoriyamu zvinodiwa. Yedu miitiro yeMIM inotitendera kuburitsa emhando yepamusoro simbi zvikamu zvine yakaoma geometries uye yakasimba kushivirira. Kunyangwe iwe uchida zvidiki, zvakaomarara zvikamu kana zvikamu zvakakura, mhinduro dzedu dzeMIM dzinogona kuzadzisa zvaunoda. Nehunyanzvi hwedu muMIM tekinoroji, tinokwanisa kupa mhinduro dzinoshanda uye dzinodhura dzekugadzirwa kwako kwesimbi chikamu.

Tsika Metal Injection Molding Solutions

1、Rapid Prototyping

Tora mukana wedu wekukurumidza jekiseni kuumba masevhisi, achikubvumidza iwe kukurumidza kuwana 1K-100K zvikamu nemutengo wakaderera. Nekushandiswa kwealuminium kana simbi molds, tinovimbisa kukurumidza kutendeuka nguva, zvakananga kugadzirisa matambudziko ako ekugadzira uye kuderedza nguva-ku-musika. Yedu inoshanda jekiseni molding process inova nechokwadi chemhando yepamusoro mhedzisiro tichichengetedza mutengo-kubudirira. Vimba nesu kuendesa huwandu hwaunoda, nekukurumidza uye nemutengo, tichikubatsira kuzadzisa zvinangwa zvako zvekugadzira nemazvo.

2, Yakaderera Volume Kugadzirwa

Yedu yakaderera vhoriyamu jekiseni rekugadzira masevhisi anoitirwa kuti uwedzere kugadzirwa kwako nekuita kuti iwe ushandise yakasimba simbi mold kugadzira 100K-1M mayunitsi. Iyi nzira inovimbisa hukuru hwemhando uye kufanana panguva yese yekugadzira, zvinobudirira kuita zvaunoda kune yakakura-yakakura, chaiyo kugadzirwa inomhanya. Neruzivo rwedu uye ekucheka-kumucheto maturusi, isu tinogona kuzadzisa zvaunoda iwe uchisimudzira yepamusoro miitiro. Iwe unogona kuvimba nesu kuti tikupe iwe yakavimbika uye inoshanda yakaderera vhoriyamu jekiseni molding mhinduro dzinokubatsira iwe kuzadzisa zvinangwa zvako zvekugadzira.

Metal Injection Molding Application

Metal jekiseni molding (MIM) inyanzvi yekugadzira inowana zvikumbiro mumaindasitiri akasiyana siyana. Heino mimwe mienzaniso yakajairika:

Midziyo yekurapa neMeno:

1.Zvishandiso zvekuvhiya

2.Orthodontic brackets

3.Dental implants

Aerospace uye Dziviriro:

1.1 Zvidiki zvakaoma zvemuchadenga zvikamu

2.Missile uye munition zvikamu

3.Zvikamu zvepfuti

Motokari:

1.Injini uye zvikamu zvekutumira

2.Fuel system components

3.Sensors uye actuators

Zvemagetsi:

1.Zvibatanidza uye zviteshi

2.EMI kudzivirira zvikamu

3.Miniature switches

Consumer Goods:

1.Watch zvikamu

2.Kuvhara uye zvikamu zvakakosha

3.Precision hinges uye clasps

Industrial Equipment:

1.Valves uye fittings

2.Pombi zvikamu

3.Gears uye gearboxes

Textile Machinery:

1.Nozzles nemapini ekutungamira

2.Vabati vetsono

3.Spinnerets yekugadzirwa kwefiber

Kugadzira Simba uye Simba:

1.Turbine blades uye nozzles

2.Heat exchanger components

3.Electrical connectors uye vanobatana

Telecommunication

1.Antenna zvikamu

2.Connector housings

3.Waveguide zvikamu

Fire Sprinkler Systems:

1.Sprinkler misoro

2.Valve zvikamu

Iyi mienzaniso inomiririra chikamu chidiki chezvinogona kushandiswa zvekuumba jekiseni resimbi. Sezvo tekinoroji ichifambira mberi uye kudiwa kwepamusoro-chaiyo, yakaoma simbi zvikamu zvinowedzera, MIM inoramba ichiwedzera kuita maindasitiri matsva. Kugona kwayo kugadzira akaomesesa geometries uye kushivirira kwakasimba uku uchidzikisa marara emidziyo inoita kuti ive sarudzo inoyevedza mumaindasitiri umo nzira dzekugadzira dzechinyakare dzinogona kunge dzisingadhure kana kuita.

Metal Injection Molding Service Materials

Metal Injection Molding (MIM) inopa huwandu hwakawanda hwezvinhu zvesimbi uye alloys ekushandisa mukugadzira maitiro. Zvimwe zvinozivikanwa zvinoshandiswa muMIM zvinosanganisira:

Aluminium Alloys: Aluminium 6061, Aluminium 7075

Stainless Steel Alloys: 316L Stainless Simbi, 17-4 PH Stainless Simbi, 440C Stainless Simbi, 304 Stainless Simbi

Tool Steels: M2 Tool Steel, D2 Tool Steel, A2 Tool Steel

Carbon Steel Alloys: 1018 Carbon Steel, 1045 Carbon Steel, 1095 Carbon Steel

Low Alloy Steels: 4140 Low Alloy Steel, 8620 Low Alloy Steel

Simbi Dzakakwira-Speed: M42 High-Speed Simbi, M4 High-Speed Simbi

Mhangura Alloys: Copper-Tin Alloys, Copper-Nickel Alloys

Titanium Alloys: Ti-6Al-4V (Grade 5), Ti-6Al-7Nb

Tungsten Alloys: Tungsten-Nickel-Copper Alloys

Precious Metal Alloys: Gold Alloys, Silver Alloys

Magnetic Alloys: Soft Magnetic Alloys (semuenzaniso, 49%Ni-Fe)

Cobalt Alloys: Cobalt-Chromium Alloys (semuenzaniso, CoCrMo)

Iron Alloys: Sintered Iron, Soft Magnetic Iron, Ductile Iron

Carbide Zvishandiso: Tungsten Carbide (WC), Cemented Carbide

Cermet Zvishandiso: Titanium Carbide (TiC) Cermet, Chromium Carbide (Cr3C2) Cermet

Zvinhu izvi zvinopa huwandu hwakasiyana hwezvivakwa uye hunhu, zvichibvumira kugadzirwa kweakasiyana uye emhando yepamusoro simbi zvikamu kuburikidza neMIM maitiro.