01

Au'aunaga fa'ameamea fa'ameamea Au'aunaga fa'ameamea

La matou Au'aunaga Fa'ameamea

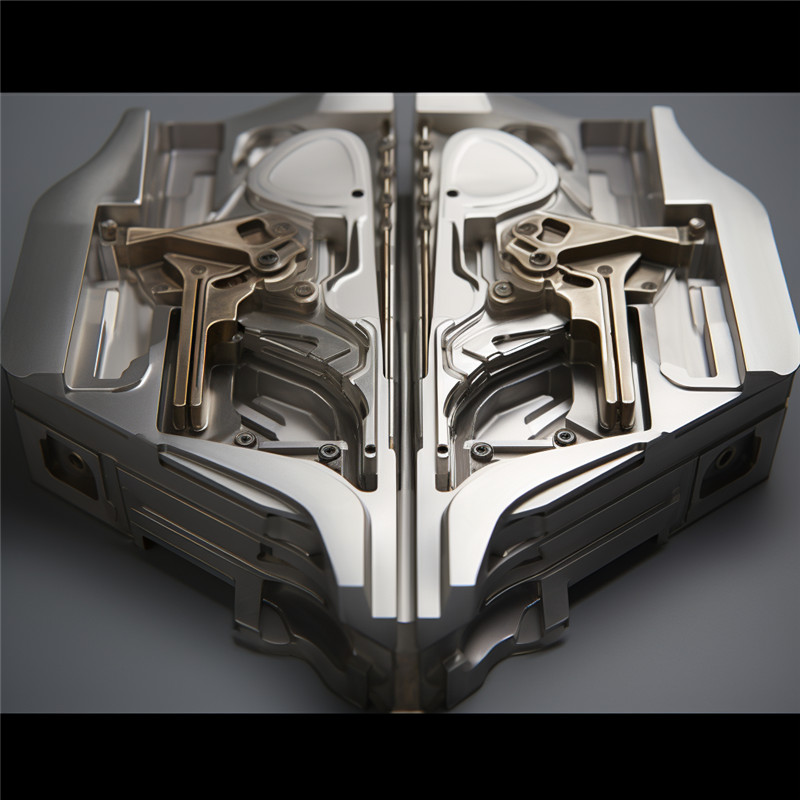

E ala i le fa'aogaina o vaifofo a le Bushang's Metal Injection Moulding (MIM) i Saina, o lo'o ia i matou le agava'a e fa'atusa ai vaega u'amea e fa'atatau i lo latou lapo'a, lavelave, ma mea e mana'omia. O la matou MIM faʻagasologa e mafai ai ona matou gaosia vaega uʻamea maualuga ma faʻataʻitaʻiga lavelave ma faʻapalepale mau. Pe e te manaʻomia ni vaega laiti, lavelave poʻo ni vaega tetele, o matou MIM fofo e mafai ona fetaui ma ou manaʻoga patino. Faatasi ai ma o matou tomai i tekinolosi MIM, e mafai ona matou tuʻuina atu fofo lelei ma taugofie mo lau gaosiga o vaega uʻamea.

Fofo fa'apipi'i tui fa'apitoa

1, Fa'ata'ita'iga vave

Faʻaaoga lelei a matou auaunaga faʻapipiʻi vave, faʻatagaina oe e vave maua le 1K-100K iunite i se tau maualalo. Faatasi ai ma le faʻaogaina o le alumini poʻo le uʻamea uʻamea, matou te faʻamautinoa taimi vave liliu, faʻafeiloaʻi saʻo au luʻitau gaosiga ma faʻaitiitia le taimi-i-maketi. O la matou fa'agasologa lelei o tui e fa'amautinoa ai le maualuga o taunu'uga a'o fa'atumauina le tau-lelei. Fa'alagolago ia i matou e momoli atu le aofa'i e te mana'omia, vave ma taugofie, fesoasoani ia te oe e fa'ataunu'u lelei au sini.

2、Lova Volume Gaosiga

O a matou auaunaga faʻapipiʻi tui maualalo e faʻamoemoe e faʻateleina lau gaosiga o gaosiga e ala i le faʻatagaina oe e faʻaogaina uʻamea uʻamea umi e maua ai le 100K-1M iunite. O lenei metotia e faʻamaonia ai le maualuga ma le tutusa i le faagasologa o le gaosiga atoa, faʻafetaui lelei lou manaʻoga mo le tele-tele, faʻatautaia saʻo. Faatasi ai ma lo matou malamalama ma meafaigaluega faʻapitoa, e mafai ona matou faʻataunuʻuina ou manaʻoga aʻo lagolagoina tulaga maualuga. E mafai ona e faʻalagolago ia i matou e tuʻuina atu ia te oe faʻalagolago ma aoga faʻaogaina vaifofo tui e fesoasoani ia te oe e ausia au sini gaosiga.

Fa'aogaina o le fa'aogaina o u'amea

u'amea tui tui (MIM) o se faiga gaosiga tele e maua ai talosaga i alamanuia eseese. O nisi nei o fa'ata'ita'iga masani:

Meafaigaluega Fomai ma Nifo:

1. Meafaigaluega tipitipi

2.Orthodontic puipui

3. Totoga nifo

Aerospace ma Puipuiga:

1.1Laiti vaega lavelave aerospace

2.Missile ma auupega vaega

3. Vaega fana

Ta'avale:

1. Inisinia ma felauaiga vaega

2. Fuel system vaega

3.Sensors ma actuators

Fa'aeletonika:

1. Connectors ma terminals

2.EMI vaega puipui

3. Sui laiti

Oloa Fa'atau:

1. Matamata vaega

2.Loka ma vaega autu

3.Precision fa'amau ma fa'amau

Meafaigaluega Alamanuia:

1. Valve ma mea faʻapipiʻi

2.Pamu vaega

3. Gears ma gearboxes

Mesini ie:

1. Nozzles ma pine taiala

2. U'u nila

3. Spinnerets mo le gaosiga o fiber

Malosiaga ma Malosiaga:

1. La'au ma fa'asuavai

2. Fa'aliliuga vevela vaega

3. Fesoʻotaʻiga eletise ma fesoʻotaʻiga

Feso'ota'iga:

1.Antenna vaega

2.Connector fale

3.Waveguide vaega

Faiga Fuimu:

1. Fa'aulu ulu

2.Valve vaega

O nei fa'ata'ita'iga e fa'atusalia na'o se vaega o le fa'aogaina e ono fa'aogaina mo le fa'ameamea tui. A o agaʻi i luma tekinolosi ma le manaʻoga mo le saʻo maualuga, faʻateleina vaega uʻamea lavelave, o loʻo faʻaauau pea ona faʻalauteleina le MIM i pisinisi fou. O lona gafatia e gaosia ai geometries lavelave ma fa'apalepale a'o fa'aitiitiga otaota meafaitino e avea ai ma filifiliga mata'ina i alamanuia e ono fa'aitiitia ai le tau po'o le fa'aogaina o metotia fa'aleaganu'u.

Meafaigaluega Au'aunaga Fa'ameamea

Metal Injection Molding (MIM) o loʻo ofoina atu le tele o mea uʻamea ma uʻamea mo le faʻaogaina i le gaosiga o gaosiga. O nisi mea masani e faʻaaogaina i le MIM e aofia ai:

Alumini Aluminum: Alumini 6061, Alumini 7075

Uamea uamea uamea: 316L uamea uamea, 17-4 PH uamea uamea, 440C uamea, 304 uamea uamea.

Uamea Meafaigaluega: M2 Meafaigaluega Uamea, D2 Meafaigaluega Uamea, A2 Meafaigaluega Uamea

Uamea uamea uamea: 1018 uamea uamea, 1045 uamea uamea, 1095 uamea uamea

u'amea u'amea maualalo: 4140 u'amea maualalo maualalo, 8620 u'amea maualalo

Uamea Saosaoa: M42 Uamea Saosaoa, M4 Uamea Saosaoa

Alu 'apamemea: 'apa 'apa-apa, 'apamemea-nikeli

Fa'au'u Titanium: Ti-6Al-4V (Vaega 5), Ti-6Al-7Nb

Tungsten Alloys: Tungsten-Nikel-Copper Alloys

Fa'amea U'amea Taua: Fa'amea Auro, Fa'amea Silver

Alu maneta: Alu maneta vaivai (fa'ata'ita'iga, 49%Ni-Fe)

Alloy Cobalt: Alloy Cobalt-Chromium (fa'ata'ita'iga, CoCrMo)

U'amea uamea: U'amea Sintered, U'amea maneta vaivai, U'amea u'amea

Mea fa'ameamea: Tungsten Carbide (WC), Carbide Sima

Mea Fa'akomepi: Titanium Carbide (TiC) Cermet, Chromium Carbide (Cr3C2) Cermet

O nei meafaitino e ofoina atu le tele o mea totino ma uiga, faʻatagaina mo le gaosiga o vaega eseese ma maualuga uʻamea e ala i le MIM process.