01

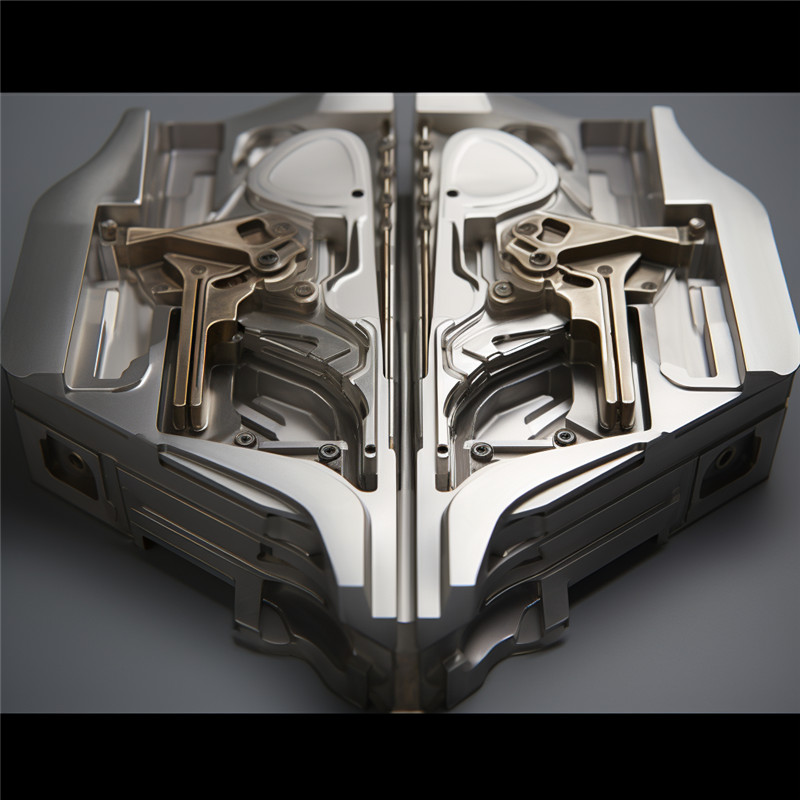

Metal Injection Molding Service Custom Injection Molding Service

Ntchito Yathu Yopangira Metal Injection

Pogwiritsa ntchito njira za Busang's Metal Injection Molding (MIM) ku China, tili ndi kuthekera kopanga zitsulo potengera kukula kwake, kukhwima, komanso kuchuluka kwake. Njira yathu ya MIM imatilola kupanga zitsulo zapamwamba kwambiri zokhala ndi ma geometries ovuta komanso kulolerana kolimba. Kaya mukufuna tizigawo tating'ono, zovuta kapena zazikulu, mayankho athu a MIM amatha kukwaniritsa zosowa zanu. Ndi ukatswiri wathu muukadaulo wa MIM, titha kukupatsani mayankho ogwira mtima komanso otsika mtengo pakupanga gawo lanu lachitsulo.

Custom Metal Injection Molding Solutions

1, Rapid Prototyping

Gwiritsani ntchito mwayi wathu wopangira jakisoni mwachangu, kukulolani kuti mupeze mayunitsi a 1K-100K mwachangu pamtengo wotsika. Pogwiritsa ntchito nkhungu za aluminiyamu kapena zitsulo, timatsimikizira nthawi yosinthira mwachangu, kuthana ndi zovuta zanu zopanga ndikuchepetsa nthawi yogulitsa. Njira yathu yabwino yopangira jekeseni imatsimikizira zotsatira zamtengo wapatali ndikusunga ndalama. Tikhulupirireni kuti tidzakupatsani kuchuluka komwe mukufuna, mwachangu komanso moyenera, kukuthandizani kukwaniritsa zolinga zanu zopanga bwino.

2, Low Volume Production

Ntchito zathu zopangira ma jakisoni otsika amapangidwa kuti ziwonjezere zomwe mumapanga pokulolani kugwiritsa ntchito nkhungu zolimba zachitsulo kuti mupange mayunitsi a 100K-1M. Njira iyi imatsimikizira kudalirika komanso kufananiza panthawi yonse yopanga, ndikukwaniritsa zomwe mukufuna pakupanga kwakukulu komanso kolondola. Ndi chidziwitso chathu ndi zida zotsogola, titha kukwaniritsa zosowa zanu ndikusunga miyezo yapamwamba kwambiri. Mutha kudalira ife kuti tikupatseni mayankho odalirika komanso othandiza opangira ma jakisoni otsika omwe amakuthandizani kukwaniritsa zolinga zanu zopanga.

Metal Injection Molding Application

Metal injection molding (MIM) ndi njira yopangira zinthu zosiyanasiyana yomwe imapezeka m'mafakitale osiyanasiyana. Nazi zitsanzo zodziwika bwino:

Zida Zachipatala ndi Zamano:

1.Zida zopangira opaleshoni

2.Mabokosi a Orthodontic

3.Kuyika mano

Zamlengalenga ndi Chitetezo:

1.1 Tizigawo tating'ono tating'ono tamlengalenga

2.Missile ndi zida zankhondo

3.Zigawo zamoto

Zagalimoto:

1.Injini ndi magawo opatsirana

2.Zigawo zamafuta amafuta

3.Masensa ndi ma actuators

Zamagetsi:

1.Zolumikizira ndi ma terminals

2.EMI zigawo zoteteza

3.Zosintha zazing'ono

Katundu Wogula:

1.Penyani zigawo

2.Lock ndi zigawo zikuluzikulu

3.Mahinji olondola ndi zomangira

Zida Zamakampani:

1.Mavavu ndi zotengera

2.Pampu zigawo

3.Magiya ndi ma gearbox

Makina Opangira Zovala:

1.Nozzles ndi zikhomo zowongolera

2.Zotengera singano

3.Spinnerets yopanga CHIKWANGWANI

Kupanga Mphamvu ndi Mphamvu:

1.Masamba a Turbine ndi ma nozzles

2.Zigawo zowonjezera kutentha

3.Zolumikizira zamagetsi ndi zolumikizirana

Matelefoni:

1.Zigawo za mlongoti

2.Nyumba zolumikizira

3.Waveguide zigawo

Makina Ozimitsa Moto:

1.Mitu yowaza

2.Zigawo za valve

Zitsanzozi zikuyimira kachigawo kakang'ono ka ntchito zomwe zingatheke poumba jekeseni wazitsulo. Pamene luso lamakono likupita patsogolo komanso kufunikira kwazitsulo zapamwamba kwambiri, zovuta zazitsulo zikuwonjezeka, MIM ikupitiriza kukula kukhala mafakitale atsopano. Kutha kwake kupanga ma geometries odabwitsa komanso kulolerana molimba pomwe kuchepetsa zinyalala zakuthupi kumapangitsa kukhala chisankho chokongola m'mafakitale momwe njira zopangira zachikhalidwe zimatha kukhala zotsika mtengo kapena zothandiza.

Zida Zopangira jekeseni wazitsulo

Metal Injection Molding (MIM) imapereka zida zambiri zachitsulo ndi ma alloys kuti zigwiritsidwe ntchito popanga. Zina mwazinthu zomwe zimagwiritsidwa ntchito mu MIM ndi:

Aluminiyamu Aloyi: Aluminiyamu 6061, Aluminiyamu 7075

Zitsulo Zosapanga dzimbiri: 316L Chitsulo chosapanga dzimbiri, 17-4 PH Chitsulo chosapanga dzimbiri, 440C Chitsulo chosapanga dzimbiri, 304 Chitsulo chosapanga dzimbiri

Zida Zitsulo: M2 Tool Steel, D2 Tool Steel, A2 Tool Steel

Mafuta a Carbon Steel: 1018 Carbon Steel, 1045 Carbon Steel, 1095 Carbon Steel

Zitsulo Zochepa: 4140 Chitsulo Chotsika, 8620 Chitsulo Chotsika

Zitsulo Zothamanga Kwambiri: M42 High-Speed Steel, M4 High-Speed Steel

Ma Aloyi a Copper: Aloyi a Copper-Tin, Aloyi a Copper-Nickel

Titaniyamu Aloyi: Ti-6Al-4V (Giredi 5), Ti-6Al-7Nb

Ma Aloyi a Tungsten: Tungsten-Nickel-Copper Alloys

Zitsulo Zamtengo Wapatali: Zosakaniza za Golide, Zosakaniza za Siliva

Maginito Aloyi: Soft Magnetic Alloys (monga 49%Ni-Fe)

Mafuta a Cobalt: Cobalt-Chromium Aloys (mwachitsanzo, CoCrMo)

Ma Iron Alloys: Sintered Iron, Soft Magnetic Iron, Ductile Iron

Zida za Carbide: Tungsten Carbide (WC), Simenti Carbide

Zida za Cermet: Titanium Carbide (TiC) Cermet, Chromium Carbide (Cr3C2) Cermet

Zidazi zimapereka katundu ndi makhalidwe osiyanasiyana, zomwe zimapangitsa kuti pakhale zitsulo zosiyanasiyana komanso zapamwamba kwambiri kudzera mu ndondomeko ya MIM.