01

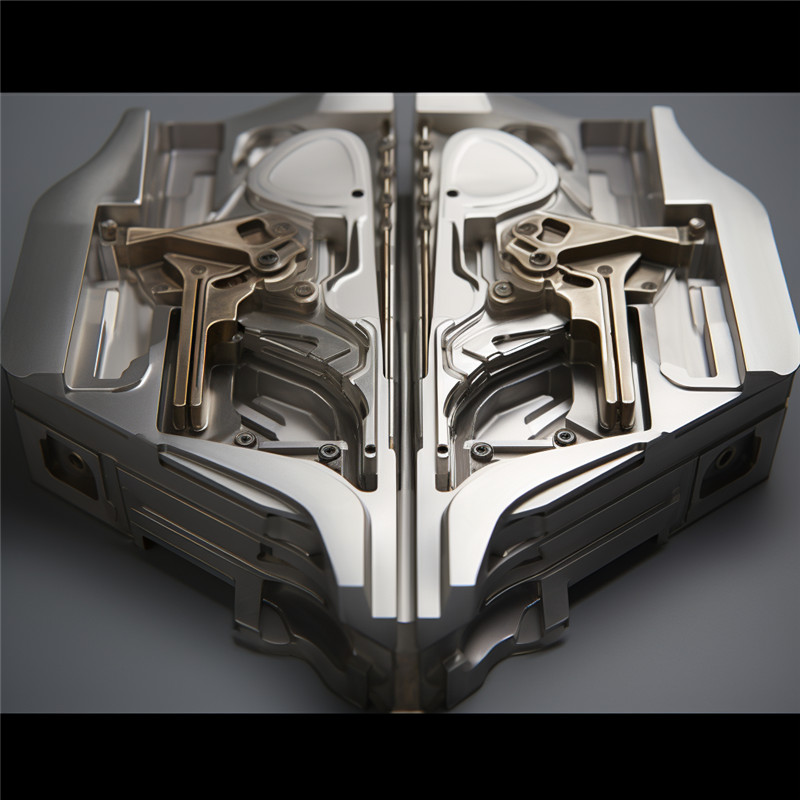

Ọrụ Injection ịkpụzi Ọrụ Omenala Injection Molding Service

Ọrụ Ịkpụzi Ịba Ọkpụkpụ Igwe Anyị

Site n'iji Bushang's Metal Injection Molding (MIM) ngwọta na China, anyị nwere ike ịkpụzi akụkụ igwe dabere na nha ha, mgbagwoju anya, na ihe ndị chọrọ olu. Usoro MIM anyị na-enye anyị ohere ịmepụta akụkụ ọla dị elu nke nwere geometry siri ike yana nnabata siri ike. Ma ị chọrọ obere ihe mgbagwoju anya ma ọ bụ akụkụ buru ibu, ngwọta MIM anyị nwere ike gboo mkpa gị. Site na nka anyị na teknụzụ MIM, anyị nwere ike ịnye ngwọta dị mma na nke dị ọnụ ala maka mmepụta akụkụ ígwè gị.

Omenala Metal Injection Molding Solutions

1. Ngwa ngwa prototyping

Jiri ohere anyị na-akpụzi injection ngwa ngwa, na-enye gị ohere ịnweta nkeji 1K-100K ọsọ ọsọ na ọnụ ala. Site na iji aluminom ma ọ bụ nchara nchara, anyị na-ekwe nkwa oge ntụgharị ngwa ngwa, na-ekwu okwu ịma aka mmepụta gị ozugbo yana ibelata oge na-ere ahịa. Usoro ịkpụzi injection anyị nke ọma na-eme ka nsonaazụ dị elu ma na-ejigide ọnụ ahịa. Tụkwasa anyị obi ịnapụta ọnụọgụ ndị ịchọrọ, ngwa ngwa na ọnụ ọnụ, na-enyere gị aka imezu ebumnuche mmepụta gị nke ọma.

2, Ala Volume Production

Arụ ọrụ ịkpụzi obere olu anyị bụ iji bulie mmepụta mmepụta gị site n'inye gị ohere iji igwe na-adịgide adịgide na-emepụta nkeji 100K-1M. Usoro a na-ekwe nkwa ịdị elu dị elu na ịdị n'otu n'oge usoro mmepụta niile, na-emezu ihe achọrọ gị nke ọma maka nnukwu mmepụta na-aga nke ọma. Site na ihe ọmụma anyị na ngwa ngwa, anyị nwere ike imezu mkpa gị ma na-akwado ụkpụrụ kachasị elu. Ị nwere ike ịdabere na anyị iji nye gị ngwọta ịkpụzi injection dị ala dị irè ma dị irè nke na-enyere gị aka imezu ebumnuche mmepụta gị.

Ngwa Ịkpụzi Injection Metal

Ịkpụzi injection metal (MIM) bụ usoro nrụpụta nke na-achọta ngwa n'ofe ụlọ ọrụ dị iche iche. Nke a bụ ụfọdụ atụ nkịtị:

Ngwa ahụike na eze:

1. Ngwa ịwa ahụ

2. Orthodontic brackets

3.Dental implants

Aerospace na nchekwa:

1.1Obere ihe mgbagwoju anya ikuku

2.Missile na ngwa agha components

3.Firearm components

Ụgbọala:

1.Engine na nnyefe akụkụ

2.Fuel usoro components

3.Sensọ na actuators

Eletrọnịkị:

1.Connectors na ọnụ

2.EMI ihe nchebe

3.Obere mgba ọkụ

Ngwa ahịa:

1.Watch components

2.Lock na isi components

3.Precision hinges na mgbachi

Akụrụngwa ụlọ ọrụ:

1.Valves na akwa akwa

2.Pump components

3.Gears na igbe igbe

Igwe akwa:

1.Nozzles na ntụ ntụ

2. Ndị na-ejide agịga

3.Spinnerets maka mmepụta eriri

Ike na mmepụta ike:

1.Turbine agụba na nozzles

2.Heat Exchanger components

3.Electrical njikọ na kọntaktị

Nzikọrịta ozi:

1.Antenna components

2. Njikọ ụlọ

3.Waveguide components

Sistemụ sprinkler ọkụ:

1.Sprinkler isi

2.Valve components

Ọmụmaatụ ndị a na-anọchi anya naanị obere akụkụ nke ngwa enwere ike ịkpụzi ịgba ọgwụ igwe. Ka teknụzụ na-aga n'ihu na ọchịchọ maka ịdị elu dị elu, akụkụ ígwè dị mgbagwoju anya na-abawanye, MIM na-aga n'ihu na-agbasawanye n'ime ụlọ ọrụ ọhụrụ. Ikike ya imepụta geometry gbagwojuru anya yana nnabata siri ike ka ọ na-ebelata ihe mkpofu ihe na-eme ka ọ bụrụ nhọrọ mara mma n'ụlọ ọrụ ebe ụzọ nrụpụta ọdịnala nwere ike ịdị obere ọnụ ma ọ bụ bara uru.

Ngwa igwe na-akpụzi injection injection

Metal Injection Molding (MIM) na-enye ihe dị iche iche nke ígwè na alloys maka iji mee ihe na nhazi usoro. Ụfọdụ ihe eji eme ihe na MIM gụnyere:

Aluminom Alloys: Aluminom 6061, Aluminom 7075

Alloys igwe anaghị agba nchara: 316L igwe anaghị agba nchara, 17-4 PH igwe anaghị agba nchara, 440C igwe anaghị agba nchara, 304 igwe anaghị agba nchara.

Ngwá Ọrụ Ngwá Ọrụ: M2 Ngwá Ọrụ Ngwá Ọrụ, Ngwá Ọrụ Ngwá Ọrụ D2, Ngwá Ọrụ A2

Alloys Carbon Steel: 1018 Carbon Steel, 1045 Carbon Steel, 1095 Carbon Steel

Alloy Alloy Steels: 4140 Alloy Alloy Steel, 8620 Alloy Alloy Steel

Igwe Ọsọ Ọsọ: M42 Igwe Ọsọ Ọsọ, M4 Igwe Ọsọ Ọsọ

Alloys ọla kọpa: ọla kọpa-Tin Alloys, ọla kọpa-Nickel Alloys

Alloys Titanium: Ti-6Al-4V (Ọkwa 5), Ti-6Al-7Nb

Alloys Tungsten: Tungsten-Nickel-Copper Alloys

Alloys ọla dị oke ọnụ ahịa: Alloys ọla edo, ọla ọla ọcha

Alloys Igwe Ọdụdọ: Alloys magnetik dị nro (dịka ọmụmaatụ, 49%Ni-Fe)

Alloys Cobalt: Cobalt-Chromium Alloys (dịka, CoCrMo)

Ígwè Alloys: Iron Sintered, Iron Magnetic dị nro, Ígwè Ductile

Ihe onwunwe Carbide: Tungsten Carbide (WC), Carbide Cemented

Akụrụngwa Cermet: Titanium Carbide (TiC) Cermet, Chromium Carbide (Cr3C2) Cermet

Ihe ndị a na-enye ihe dị iche iche na njirimara dị iche iche, na-enye ohere maka ịmepụta akụkụ dị iche iche na nke dị elu site na usoro MIM.