01

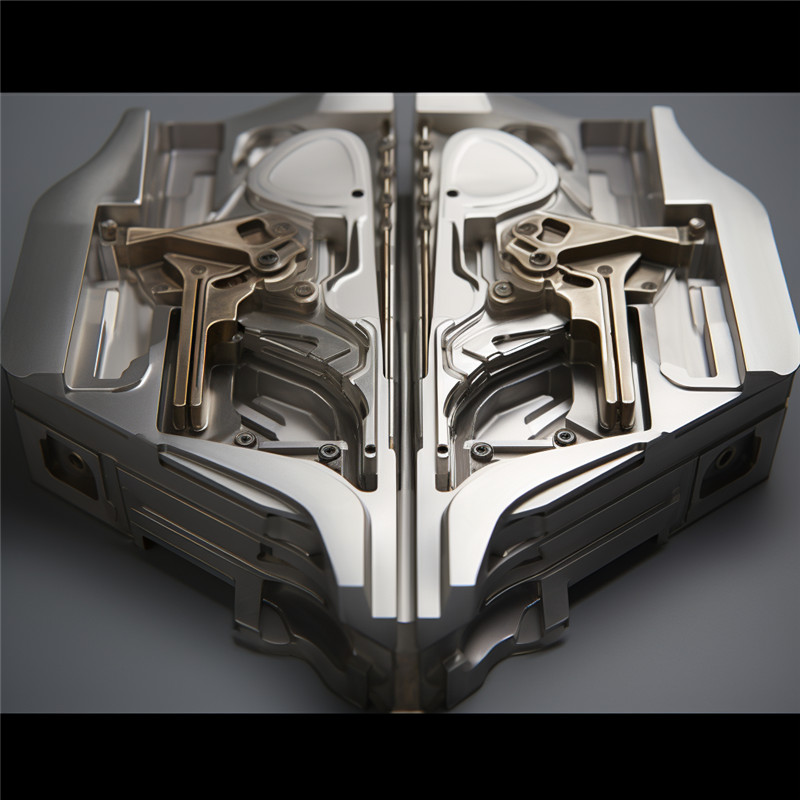

Hlau Txhaj Molding Service Custom Injection Molding Service

Peb Cov Kev Pabcuam Hlau Txhaj Molding

Los ntawm kev siv Bushang's Hlau Txhaj Moulding (MIM) cov kev daws teeb meem hauv Suav teb, peb muaj peev xwm los tsim cov khoom hlau raws li lawv qhov loj me, qhov tsis sib xws, thiab ntim raws li qhov xav tau. Peb cov txheej txheem MIM tso cai rau peb los tsim cov khoom hlau zoo nrog cov geometries nyuaj thiab nruj kam rau ua. Txawm hais tias koj xav tau cov khoom me me, tsis sib xws lossis qhov loj dua, peb cov kev daws teeb meem MIM tuaj yeem ua raws li koj cov kev xav tau tshwj xeeb. Nrog peb cov kws tshaj lij hauv MIM thev naus laus zis, peb tuaj yeem muab cov kev daws teeb meem zoo thiab raug nqi rau koj cov khoom siv hlau.

Kev cai Hlau Txhaj Molding Solutions

1. Ceev Prototyping

Ua kom zoo dua ntawm peb cov kev pabcuam txhaj tshuaj sai, tso cai rau koj kom tau txais 1K-100K sai sai ntawm tus nqi qis. Nrog kev siv cov txhuas los yog hlau pwm, peb lav lub sijhawm hloov pauv sai, ncaj qha daws koj cov teeb meem kev tsim khoom thiab txo lub sijhawm-rau-kev ua lag luam. Peb cov txheej txheem txhaj tshuaj molding ua tau zoo ua kom cov txiaj ntsig zoo thaum tswj hwm tus nqi zoo. Cia siab rau peb kom xa cov khoom koj xav tau, sai thiab pheej yig, pab koj ua tau raws li koj cov hom phiaj tsim khoom zoo.

2, Tsawg Volume Ntau Lawm

Peb cov kev pabcuam ntim qis qis yog tsim los ua kom koj cov khoom tsim tawm los ntawm kev ua kom koj siv cov pwm ruaj khov los tsim 100K-1M units. Cov txheej txheem no tau lees paub qhov zoo tshaj plaws thiab kev sib txig sib luag thaum lub sijhawm tag nrho cov txheej txheem tsim khoom, ua tau raws li koj qhov yuav tsum tau ua rau kev ua haujlwm loj, raug ntau lawm. Nrog rau peb cov kev paub thiab cov cuab yeej txiav, peb tuaj yeem ua tiav koj cov kev xav tau thaum txhawb nqa cov qauv siab tshaj plaws. Koj tuaj yeem tso siab rau peb los muab koj cov kev ntseeg siab thiab ua tau zoo uas tsis tshua muaj kev txhaj tshuaj molding kev daws teeb meem uas pab koj ua tiav koj lub hom phiaj tsim khoom.

Hlau Txhaj Molding Daim Ntawv Thov

Hlau txhaj tshuaj molding (MIM) yog txheej txheem tsim khoom siv ntau yam uas pom cov ntawv thov thoob plaws ntau qhov kev lag luam. Nov yog qee qhov piv txwv:

Cov cuab yeej kho mob thiab kho hniav:

1. Cov cuab yeej phais mob

2. Orthodontic brackets

3. Kev cog hniav

Aerospace thiab Defense:

1.1 Me me complex aerospace Cheebtsam

2.Missile thiab munition Cheebtsam

3. Cov khoom siv phom phom

Automotive:

1.Engine thiab kis qhov chaw

2. Roj system Cheebtsam

3.Sensors thiab actuators

Electronics:

1.Connectors thiab terminals

2.EMI shielding Cheebtsam

3. Cov keyboards me me

Cov khoom siv:

1. Saib cov khoom siv

2. Xauv thiab cov khoom tseem ceeb

3.Precision hinges thiab clasps

Khoom siv:

1.Valves thiab fittings

2. Cov twj tso kua mis

3.Gears thiab gearboxes

Textile Machinery:

1.Nozzles thiab coj tus pins

2. Koob tuav

3.Spinnerets rau fiber ntau lawm

Lub zog thiab lub zog tsim:

1.Turbine hniav thiab nozzles

2.Heat exchanger Cheebtsam

3.Electrical connectors thiab kev sib cuag

Kev Sib Txuas Lus:

1. Kav hlau txais xov Cheebtsam

2.Connector vaj tse

3.Waveguide Cheebtsam

Hluav Taws Sprinkler Systems:

1. Sprinkler taub hau

2.Valve Cheebtsam

Cov piv txwv no tsuas yog ib feem ntawm cov ntawv thov rau kev txhaj tshuaj hlau. Raws li kev siv thev naus laus zis thiab kev thov rau qhov siab-precision, complex hlau qhov chaw nce, MIM txuas ntxiv mus rau kev lag luam tshiab. Nws lub peev xwm los tsim cov geometries intricate thiab nruj tolerances thaum txo cov khoom pov tseg ua rau nws yog ib qho kev xaiv zoo nkauj hauv kev lag luam uas cov txheej txheem kev tsim khoom ib txwm muaj tsawg dua los yog siv tau.

Hlau Txhaj Molding Service Cov ntaub ntawv

Hlau Txhaj Moulding (MIM) muaj ntau yam ntawm cov ntaub ntawv hlau thiab alloys siv rau hauv kev tsim khoom. Qee cov ntaub ntawv siv hauv MIM suav nrog:

Aluminium Alloys: Aluminium 6061, Aluminium 7075

Stainless hlau Alloys: 316L Stainless hlau, 17-4 PH Stainless hlau, 440C Stainless hlau, 304 Stainless hlau

Cov cuab yeej hlau: M2 cuab yeej hlau, D2 cuab yeej hlau, A2 cuab yeej hlau

Carbon Steel Alloys: 1018 Carbon Steel, 1045 Carbon Steel, 1095 Carbon Steel

Tsawg Alloy Steels: 4140 Low Alloy Steel, 8620 Low Alloy Steel

High-Speed Steels: M42 High-Speed Steel, M4 High-Speed Steels

Copper Alloys: Copper-Tin Alloys, Tooj-Nickel Alloys

Titanium Alloys: Ti-6Al-4V (Qib 5), Ti-6Al-7Nb

Tungsten Alloys: Tungsten-Nickel-Copper Alloys

Cov Hlau Hlau Zoo Tshaj: Kub Alloys, Nyiaj Alloys

Sib Nqus Alloys: Mos Sib Nqus Alloys (xws li, 49% Ni-Fe)

Cobalt Alloys: Cobalt-Chromium Alloys (piv txwv li, CoCrMo)

Hlau Alloys: Sintered Hlau, Mos Sib Nqus Hlau, Hlau Hlau

Cov Khoom Siv Carbide: Tungsten Carbide (WC), Cemented Carbide

Cov ntaub ntawv Cermet: Titanium Carbide (TiC) Cermet, Chromium Carbide (Cr3C2) Cermet

Cov ntaub ntawv no muaj ntau yam khoom thiab cov yam ntxwv, tso cai rau kev tsim cov khoom sib txawv thiab cov hlau zoo los ntawm cov txheej txheem MIM.