01

ʻO ka lawelawe hoʻoheheʻe ʻana metala

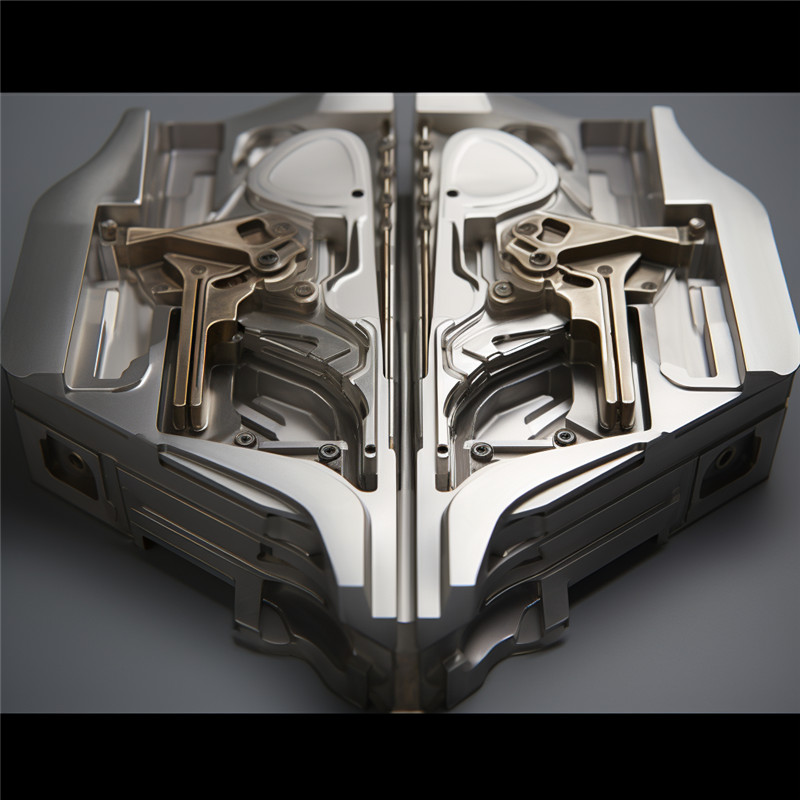

ʻO kā mākou lawelawe hoʻoheheʻe metala

Ma ka hoʻohana ʻana i nā ʻōnaehana Metal Injection Molding (MIM) ʻo Bushang ma Kina, hiki iā mākou ke hana i nā ʻāpana metala e pili ana i ko lākou nui, paʻakikī, a me nā koi nui. ʻO kā mākou kaʻina MIM hiki iā mākou ke hana i nā ʻāpana metala kiʻekiʻe me nā geometries paʻakikī a me nā hoʻomanawanui paʻa. Inā makemake ʻoe i nā ʻāpana liʻiliʻi, paʻakikī a i ʻole nā ʻāpana nui, hiki i kā mākou MIM solutions ke hoʻokō i kāu mau pono kikoʻī. Me ko mākou akamai i ka ʻenehana MIM, hiki iā mākou ke hāʻawi i nā hopena maikaʻi a maikaʻi hoʻi no kāu hana ʻāpana metala.

Hoʻoheheʻe ʻia ʻo Metala Injection Molding Solutions

1、Rapid Prototyping

E hoʻohana i kā mākou lawelawe hoʻoheheʻe wikiwiki, e ʻae iā ʻoe e kiʻi koke i nā ʻāpana 1K-100K ma ke kumu kūʻai haʻahaʻa. Me ka hoʻohana ʻana i ka alumini a i ʻole ke kila kila, ke hōʻoiaʻiʻo nei mākou i nā manawa huli wikiwiki, e hoʻoponopono pololei i kāu mau pilikia hana a hoʻemi i ka manawa-i-makeke. ʻO kā mākou kaʻina hana hoʻoheheʻe injection e hōʻoiaʻiʻo i nā hopena kiʻekiʻe me ka mālama ʻana i ke kumukūʻai. E hilinaʻi iā mākou e hāʻawi i nā nui āu e pono ai, me ka wikiwiki a me ka hiki ke kōkua iā ʻoe e hoʻokō pono i kāu mau pahuhopu hana.

2、Haʻahaʻa Volume Production

ʻO kā mākou mau lawelawe hoʻoheheʻe haʻahaʻa haʻahaʻa i manaʻo ʻia e hoʻonui i kāu huahana hana ma o ka ʻae ʻana iā ʻoe e hoʻohana i nā pahu kila paʻa e hana i nā ʻāpana 100K-1M. Mālama kēia ʻano hana i ka maikaʻi a me ka like ʻole i ka wā o ke kaʻina hana holoʻokoʻa, e hoʻokō pono i kāu koi no ka holo ʻana o ka hana nui a pololei. Me ko mākou ʻike a me nā mea hana ʻokiʻoki, hiki iā mākou ke hoʻokō i kāu mau pono me ka mālama ʻana i nā kūlana kiʻekiʻe. Hiki iā ʻoe ke hilinaʻi iā mākou e hāʻawi iā ʻoe i nā hopena hoʻoheheʻe haʻahaʻa haʻahaʻa haʻahaʻa e kōkua iā ʻoe e hoʻokō i kāu mau pahuhopu.

Palapala Hoʻoheheʻe Metala

ʻO ka hoʻoheheʻe ʻia ʻana o ka metal (MIM) kahi hana hana maʻamau e ʻike ai i nā noi ma nā ʻoihana like ʻole. Eia kekahi mau laʻana maʻamau:

Lapaʻau a me nā mea niho:

1. ʻO nā mea hana ʻokiʻoki

2.Orthodontic brackets

3.Niho implants

Aerospace a me ka pale:

1.1 ʻO nā ʻāpana aerospace liʻiliʻi paʻakikī

2.Missile a me nā mea kaua

3.Firearm mau mea

Kaʻa:

1.Engine a me nā'āpana hoʻoili

2.Fuel pūnaewele mea

3.Sensors a me nā mea hana

Mea uila:

1.Connectors a me nā terminals

2.EMI mea pale

3. Nā hoʻololi liʻiliʻi

Consumer waiwai:

1.Watch mau mea

2.Lock a me nā mea kī

3.Precision hinges a me nā kaula

Lako Hana Hana:

1.Valves a me nā pono

2. Pump mau mea

3.Gears a me nā pahu pahu

Mekini lole lole:

1. Nozzles a me nā pine alakaʻi

2.Nila paʻa

3.Spinnerets no ka hana fiber

ʻIkepili a me ka hana mana:

1. Turbine nā lau a me nā nozzles

2.Heat exchanger mau mea

3.Electrical connectors a me nā pilina

Kelepona:

1.Antenna mau mea

2.Connector hale

3.Waveguide mau mea

Pūnaehana Sprinkler ahi:

1. Nā poʻo sprinkler

2.Valve mau mea

Hōʻike kēia mau hiʻohiʻona i kahi hapa o nā noi kūpono no ka hoʻoheheʻe ʻia ʻana metala. Ke piʻi nei ka ʻenehana a me ka koi ʻana i nā ʻāpana metala paʻakikī, hoʻomau ka MIM i nā ʻoihana hou. ʻO kona hiki ke hana i nā geometries paʻakikī a me nā hoʻomanawanui paʻa ʻoiai e hōʻemi ana i ka ʻōpala waiwai e lilo ia i mea koho maikaʻi i nā ʻoihana kahi i ʻoi aku ka liʻiliʻi o nā kumu hana kuʻuna.

Mea Hana Hana Metala Injection Molding

Hāʻawi ʻo Metal Injection Molding (MIM) i kahi ākea o nā mea metala a me nā ʻāpana no ka hoʻohana ʻana i ka hana hana. Aia kekahi mau mea maʻamau i hoʻohana ʻia ma MIM:

Aluminum Alloys: Aluminum 6061, Aluminum 7075

ʻO nā mea hoʻohuihui kila: 316L Kūleʻa Kūleʻa, 17-4 PH Kūleʻa Kūleʻa, 440C Kūleʻa Kūleʻa, 304 Kūleʻa Kūleʻa

Mea kila kila: M2 mea hao kila, D2 mea hao kila, A2 mea hao kila

ʻO ka hao hao hao: 1018 Carbon Steel, 1045 Carbon Steel, 1095 Carbon Steel

ʻO nā mea hao haʻahaʻa haʻahaʻa: 4140 haʻahaʻa haʻahaʻa, 8620 haʻahaʻa

Nā Kiʻekiʻe Kiʻekiʻe: M42 High-Speed Steel, M4 High-Speed Steel

Nā Alloy Copper: Copper-Tin Alloys, Copper-Nickel Alloys

Nā Alloy Titanium: Ti-6Al-4V (Papa 5), Ti-6Al-7Nb

ʻO nā mea hui pū: Tungsten-Nickel-Copper Alloys

Nā Metala Makamae: Nā Alloy Gula, Nā Alloy Kālā

Mākēneki Alloys: Soft Magnetic Alloys (e laʻa, 49%Ni-Fe)

Nā Alloy Cobalt: Nā Alloy Cobalt-Chromium (e laʻa, CoCrMo)

Mea hao: Hao Sintered, Hao Magnetic palupalu, Hao Ductile

Nā Mea Hana: Tungsten Carbide (WC), Cemented Carbide

Nā Mea Hana Cermet: Titanium Carbide (TiC) Cermet, Chromium Carbide (Cr3C2) Cermet

Hāʻawi kēia mau mea i ka nui o nā waiwai a me nā hiʻohiʻona, e ʻae ai i ka hana ʻana i nā ʻāpana metala like ʻole a kiʻekiʻe ma o ke kaʻina MIM.