01

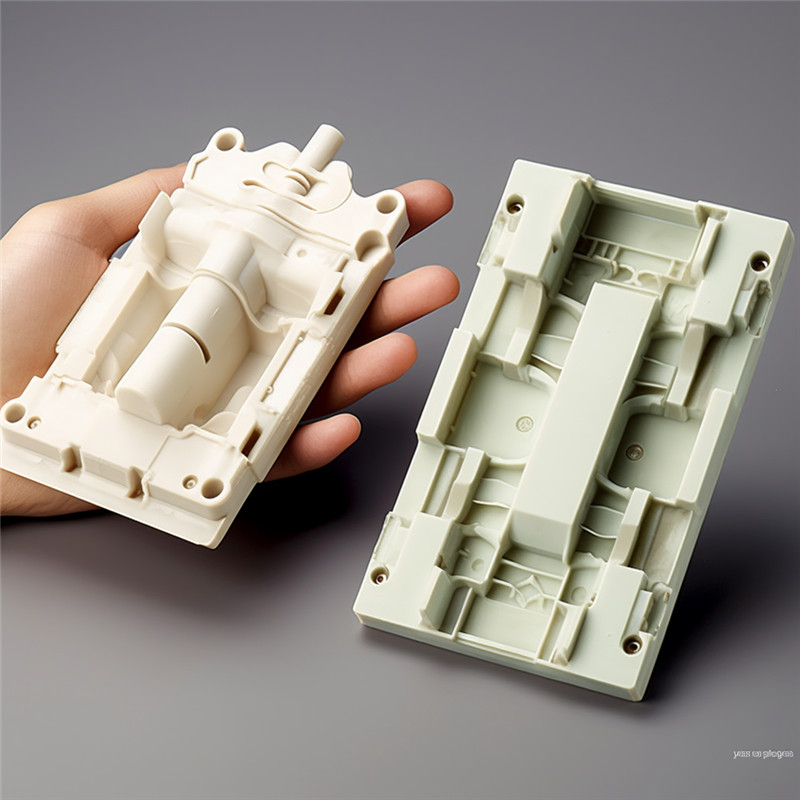

Ƙwararrun babban daidaitaccen filastik na allurar filastik tare da zane 3D

Sabbin Sabar Canjin Canjin Filastik ɗinmu

Shawarar Samfura:

Bayan yin kwatancen wani ɓangaren filastik na al'ada kuma da alama an kai gaɓar shirye-shiryen samarwa, zaɓin ƙirar allura ya zama babban abin la'akari. Wannan mataki na riga-kafi yana ba da kyakkyawar hanya zuwa:

Gano gyare-gyare: buɗe ɓangarorin ƙira da yuwuwar haɓakawa waɗanda ƙila ba za su bayyana a takarda ba.

Rage Hatsari: Haɗa ƙalubale da rashin tabbas kafin aiwatar da manyan ayyuka.

Tabbatar da Mahimmanci: Daidaita tsarin samarwa don ingantaccen daidaito da inganci.

A ƙarshe, fasahar yin gyare-gyaren allura ba mataki ba ne kawai a cikin tafiyar masana'antu; muhimmin mahimmanci ne. Yana ba wa masu ƙira da masana'anta damar kewaya cikin ɓangarorin haɓaka samfura tare da iyawa, hangen nesa, da ƙimar farashi, aza harsashi don samun nasara da ingantaccen samar da taro.

Gallery of Injection Molding Prototyping

CNC Machining Materials

Kayayyakin Ƙirƙirar Ƙirƙirar allura

Zaɓin Abubuwan Da Ya dace don Ƙirƙirar Ƙirƙirar allura

Zaɓin abin da ya dace don ƙirar ƙirar allura babban yanke shawara ne a cikin tsarin haɓaka samfur. Zaɓin ya rataya akan abubuwa kamar buƙatun aikin, ƙuntatawa na kasafin kuɗi, da takamaiman halaye masu mahimmanci ga samfurin. Daidaita tare da aikin da aka yi niyya, buƙatun aiki, da yanayin da ake tsammani samfurin zai fuskanta shine mafi mahimmanci. Samfurin gyare-gyaren allura yana ba da nau'ikan kayayyaki iri-iri, ƙarfafa masu ƙira da injiniyoyi don ƙera samfura waɗanda ke kwaikwayi kaddarorin samfurin ƙarshe da aka yi niyya. Bugu da ƙari, la'akari kamar farashi, lokacin jagora, da sauƙi na inji ko ƙarewa suna taka muhimmiyar rawa a zaɓin kayan aiki.

Thermoplastics:

ABS (Acrylonitrile Butadiene Styrene):

Properties: An san shi don ƙarfi da juriya mai tasiri.

Aikace-aikace: Yawanci ana amfani da su don yin samfura da samfuran mabukaci da abubuwan haɗin mota.

Polypropylene:

Kayayyakin: Fuskar nauyi, juriya na sinadarai.

Aikace-aikace: Ya dace da marufi, kwantena, da sassan mota.

Polyethylene:

Siffofin: HDPE (Maɗaukakin Maɗaukaki Polyethylene), LDPE (Maɗaukakin Ƙarfafa Polyethylene).

Aikace-aikace: Ana amfani da shi don samfuran kama daga kwalabe zuwa kayan wasan yara.

Polycarbonate:

Kayayyakin: Babban juriya mai tasiri, tsabtar gani.

Aikace-aikace: Mafi dacewa don nau'ikan ruwan tabarau na gani, kayan lantarki, da kayan tsaro.

Injiniyan Filastik:

Nailan (Polyamide):

Properties: ƙarfi, m, mai kyau lalacewa juriya.

Aikace-aikace: Ana amfani da su don samfuri na gears, bearings, da kayan haɗin ginin.

Polyoxymethylene (POM):

Har ila yau Known As: Acetal.

Properties: Tauri da m.

Aikace-aikace: Ana amfani da su don samfuri na sassa na inji kamar gears da bushings.

PEEK (Polyether Ether Ketone):

Properties: High-yi, m sinadaran juriya.

Aikace-aikace: Ya dace da samfura a cikin yanayi masu buƙata, kamar sararin samaniya da likita.

Elastomers:

Silicone Rubber:

Kayayyakin: Mai sassauƙa, mai juriya ga matsanancin yanayin zafi.

Aikace-aikace: Ana amfani da su don samfuran na'urorin likitanci, hatimi, da samfuran mabukata.

Bioplastics:

PLA (Polylactic Acid):

Kayayyakin: Mai yuwuwa.

Aikace-aikace: Ana amfani da su a cikin samfuran abokantaka na muhalli, galibi ana zaɓa don marufi da kayan masarufi.

A fannin yin gyare-gyaren allura, zaɓin kayan ƙayyadaddun yanke shawara ne wanda ke buƙatar yin la'akari da hankali na duka fannonin fasaha da na aiki. Kowane abu yana kawo saitin kaddarorin sa na musamman, yana ba da gudummawa ga daidaito da aiki na samfur.

Gallery of Injection Molding Prototyping