01

Sabis ɗin Gyaran Ƙarfe na Ƙarfe na Musamman Sabis na Gyaran Ƙarfe

Sabis ɗin Ƙarfe na Ƙarfe na Mu

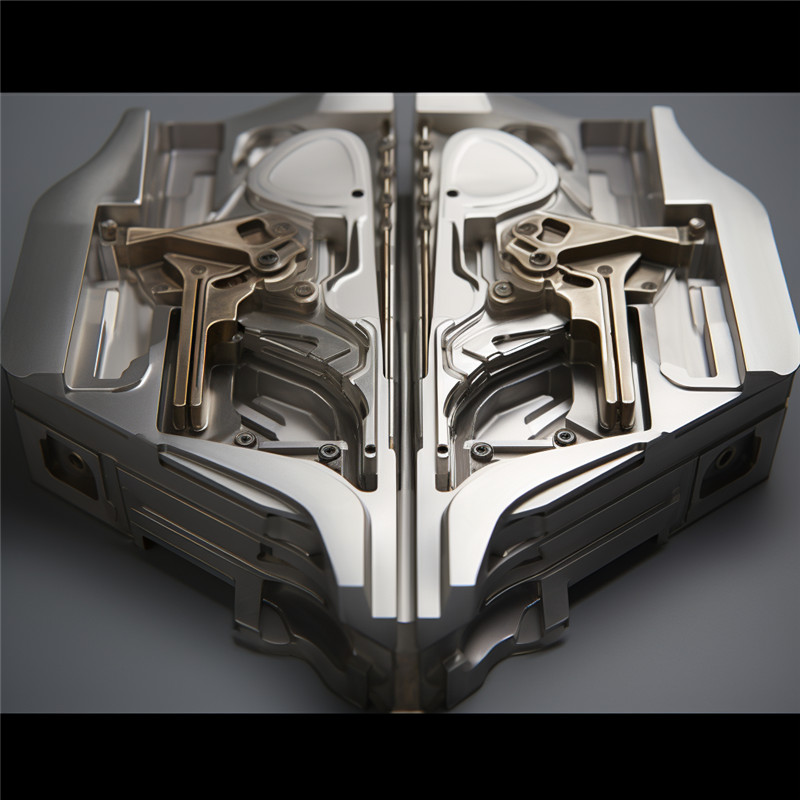

Ta hanyar amfani da mafita na Bushang's Metal Injection Molding (MIM) a China, muna da damar yin siffar sassan ƙarfe bisa girmansu, ƙaƙƙarfan ƙaƙƙarfan su, da buƙatun girma. Tsarin mu na MIM yana ba mu damar samar da sassa na ƙarfe masu inganci tare da hadaddun geometries da matsananciyar haƙuri. Ko kuna buƙatar ƙananan abubuwa masu rikitarwa ko manyan sassa, hanyoyin mu na MIM na iya biyan takamaiman bukatunku. Tare da gwanintar mu a cikin fasahar MIM, za mu iya samar da ingantacciyar mafita mai inganci don samar da sashin ƙarfe na ku.

Maganin Gyaran Ƙarfe na Musamman

1. Saurin Samfura

Yi amfani da ayyukan mu na gyaran allura da sauri, yana ba ku damar samun raka'a 1K-100K cikin sauri a farashi mai sauƙi. Tare da yin amfani da aluminum ko karfe gyare-gyare, muna bada garantin saurin juyawa, magance matsalolin samar da ku kai tsaye da rage lokaci zuwa kasuwa. Mu ingantaccen tsarin gyare-gyaren allura yana tabbatar da sakamako mai inganci yayin da yake kiyaye ƙimar farashi. Amince da mu don isar da adadin da kuke buƙata, cikin sauri da araha, yana taimaka muku cimma burin samarwa da kyau.

2. Ƙarƙashin Ƙarfafa Ƙarfafawa

Ayyukan gyaran gyare-gyaren ƙananan ƙararrakin mu an yi niyya don haɓaka kayan aikin ku ta hanyar ba ku damar amfani da ƙirar ƙarfe mai ɗorewa don samar da raka'a 100K-1M. Wannan dabarar tana ba da garantin ingantacciyar inganci da daidaito yayin duk aikin samarwa, tare da cika buƙatunku don aiwatar da manyan sikeli, ingantaccen samarwa. Tare da ilimin mu da kayan aikin yankan-baki, za mu iya biyan bukatun ku yayin da muke kiyaye mafi girman matsayi. Kuna iya dogara da mu don samar muku da ingantaccen ƙwaƙƙwaran ƙaƙƙarfan hanyoyin gyare-gyaren allura waɗanda ke taimaka muku cimma manufofin samarwa ku.

Aikace-aikacen Gyaran Ƙarfe na Ƙarfe

Ƙarfe gyare-gyaren gyare-gyare (MIM) tsari ne mai mahimmanci na masana'antu wanda ke nemo aikace-aikace a cikin masana'antu daban-daban. Ga wasu misalan gama-gari:

Na'urorin likitanci da hakori:

1.Kayan aikin tiyata

2. Maƙallan Orthodontic

3.Dental implants

Aerospace da Tsaro:

1.1 Kananan abubuwan haɗin sararin samaniya

2.Makamai da makami mai linzami

3.Firearm sassa

Mota:

1.Injiniya da sassan watsawa

2.Fuel tsarin sassan

3. Sensors da actuators

Kayan lantarki:

1.Connectors da tashoshi

2.EMI kayan kariya

3. Miniature switches

Kayayyakin Mabukaci:

1.Watch sassa

2.Lock da maɓalli masu mahimmanci

3.Precision hinges da claspps

Kayayyakin Masana'antu:

1.Bawuloli da kayan aiki

2.Pump abubuwan

3.Gears da akwatunan kaya

Injin Yadi:

1. Nozzles da jagorar fil

2.Masu rikon allura

3.Spinnerets don samar da fiber

Makamashi da Ƙarfafa Ƙarfi:

1. Turbine ruwan wukake da nozzles

2.Hanyoyin musayar zafi

3.Electrical connectors and contacts

Sadarwa:

1.Antenna sassa

2. Gidajen haɗi

3.Waveguide aka gyara

Tsarin Yada Wuta:

1.Sprinkler kawunansu

2.Bawul abubuwa

Waɗannan misalan suna wakiltar kaɗan ne na yuwuwar aikace-aikacen yin gyare-gyaren ƙarfe. Yayin da fasaha ke ci gaba da kuma buƙatar madaidaicin daidaitattun sassa na ƙarfe masu rikitarwa, MIM na ci gaba da fadada zuwa sababbin masana'antu. Ƙarfinsa na samar da rikitattun geometries da maƙarƙashiyar haƙuri yayin da rage sharar kayan abu ya sa ya zama zaɓi mai ban sha'awa a masana'antu inda hanyoyin masana'anta na gargajiya na iya zama marasa tsada ko aiki.

Kayayyakin Sabis na Injection Molding

Ƙarfe Injection Molding (MIM) yana ba da nau'i na kayan ƙarfe da kayan haɗi don amfani a cikin tsarin masana'antu. Wasu kayan gama gari da ake amfani da su a cikin MIM sun haɗa da:

Aluminum Alloys: Aluminum 6061, Aluminum 7075

Bakin Karfe Alloys: 316L Bakin Karfe, 17-4 PH Bakin Karfe, 440C Bakin Karfe, 304 Bakin Karfe

Karfe na Kayan aiki: Karfe na M2, Karfe Kayan aiki na D2, Karfe Kayan A2

Carbon Karfe Alloys: Carbon Karfe 1018, Carbon Karfe 1045, Carbon Karfe 1095

Low alloy kiraye: 4140 low alloy karfe, 8620 low alloy karfe

Ƙarfe Mai Girma: M42 Ƙarfe Mai Girma, M4 Ƙarfe Mai Girma

Alloys Copper: Copper-Tin Alloys, Copper-Nickel Alloys

Titanium Alloys: Ti-6Al-4V (Grade 5), Ti-6Al-7Nb

Tungsten Alloys: Tungsten-Nickel-Copper Alloys

Ƙarfe masu daraja: Gilashin Zinariya, Ƙarfe na Azurfa

Alloys Magnetic: Alloys Magnetic Soft (misali, 49% Ni-Fe)

Alamomin Cobalt: Alloys Cobalt-Chromium (misali, CoCrMo)

Iron Alloys: Sintered Iron, Mai taushi Magnetic Iron, Ductile Iron

Abubuwan Carbide: Tungsten Carbide (WC), Carbide Siminti

Kayayyakin Cermet: Titanium Carbide (TiC) Cermet, Chromium Carbide (Cr3C2) Cermet

Wadannan kayan suna ba da nau'i-nau'i na kaddarorin da halaye, suna ba da damar samar da sassa daban-daban da ƙananan ƙarfe ta hanyar tsarin MIM.